Plastic Injection Molding

For electronic device plastic injection molding, Seasky offers a variety of molding procedures. We can produce standard and safe-to-use plastic device parts as per the client specification through multiple processes.

Seasky focuses on the development and production of injection molded products. We assist you in all stages, including product design and development, mold design and building, material selection and injection molding.

Seasky serves you with plastic injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

Tell us your plastic molding challenges, and our expert team will provide a total solution from design to production.

We meet your production needs with professional and strict production environment control.

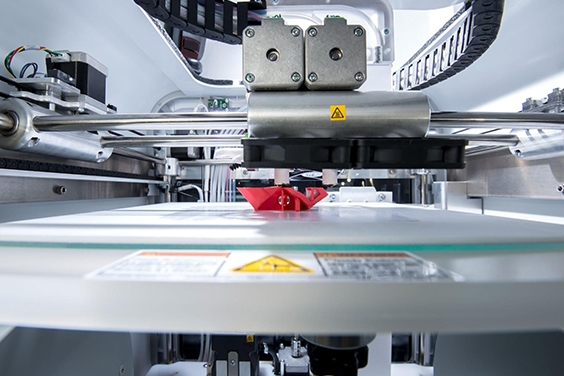

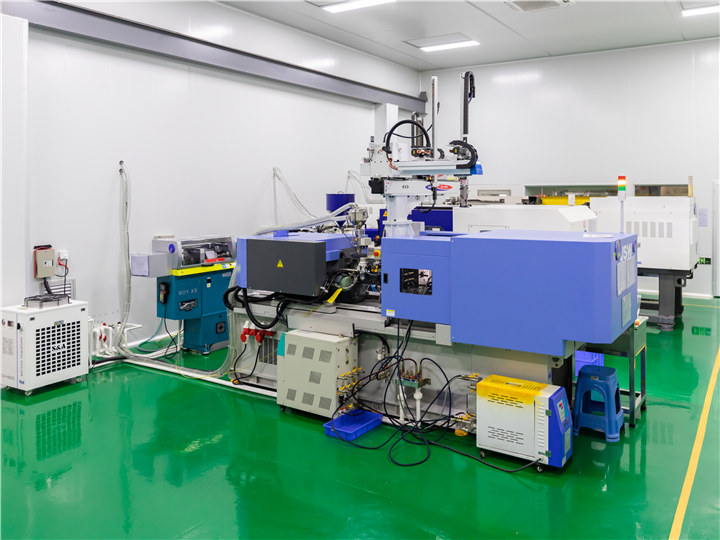

Equipped with imported precision processing equipment and high-precision injection molding machines.

Our customer support team is available 24/7 and can respond to your orders and inquiries within 12 hours.

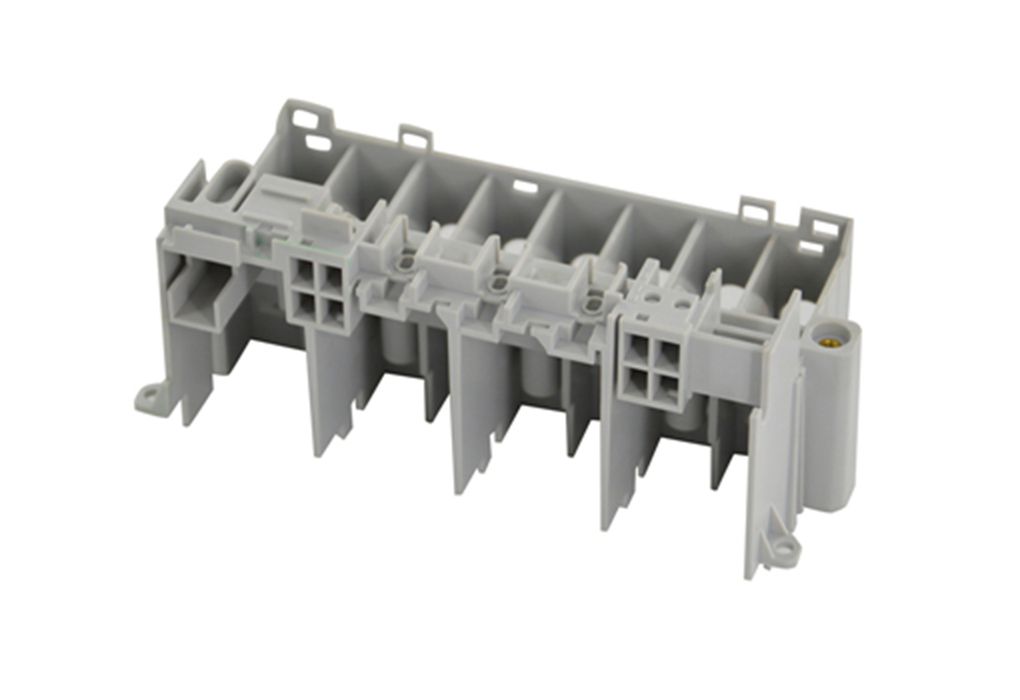

For electronic device plastic injection molding, Seasky offers a variety of molding procedures. We can produce standard and safe-to-use plastic device parts as per the client specification through multiple processes.

Seasky specializes in injection molding for the electronic sector and provides low-risk solutions. We provide professional and all-inclusive support at all stages of your project, including product development, mold design and manufacturing, material selection and injection molding production.

From start to finish, our experienced and qualified engineers work closely with you in finding an injection molding solution that addresses your business requirements.

You can simply provide us with a 3D or a 2D drawing with the tolerance requirements, and our team will design them by using various software like SolidWorks, AutoCad, Mold Flow MPI and enhance it for manufacturability.

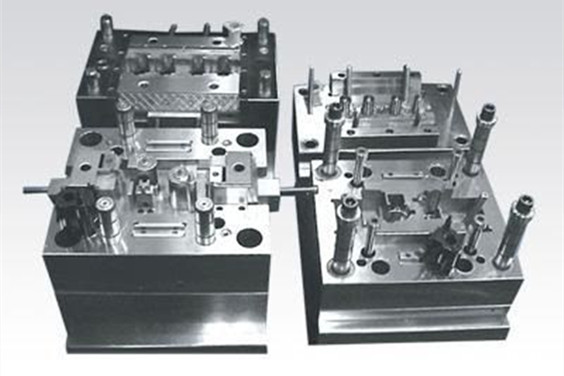

Our injection mold designers have more than 10 years of experience in designing electronic pieces and precise molds. Materials, ejection mechanisms and other factors are considered when we put forward a perfect mold tool design.

The 3D prototype is based on the finalized design by the client. Accurate proptotypind sets a precedent for mass production. Only precision methods make the 3D prototype suitable for injection molding later.

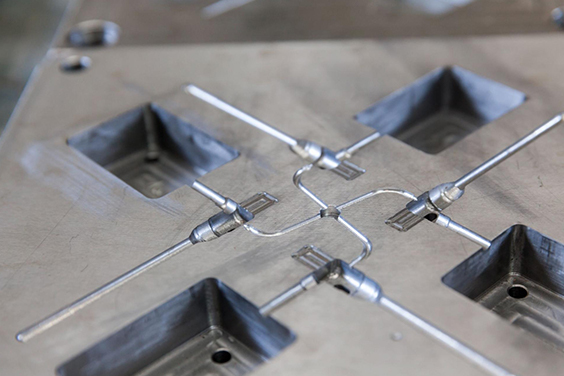

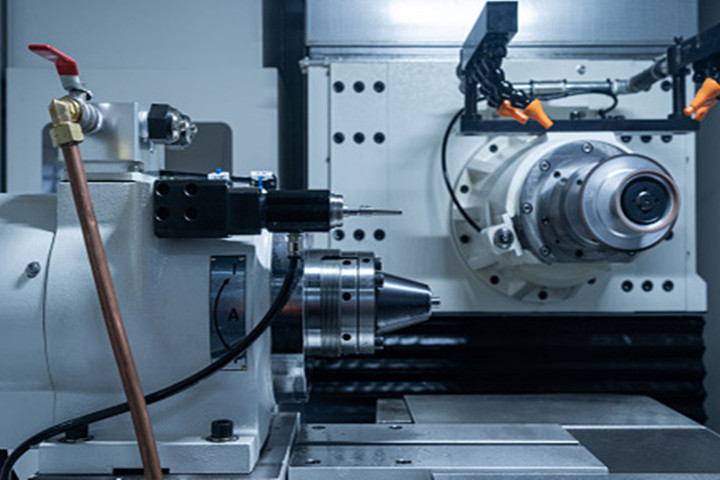

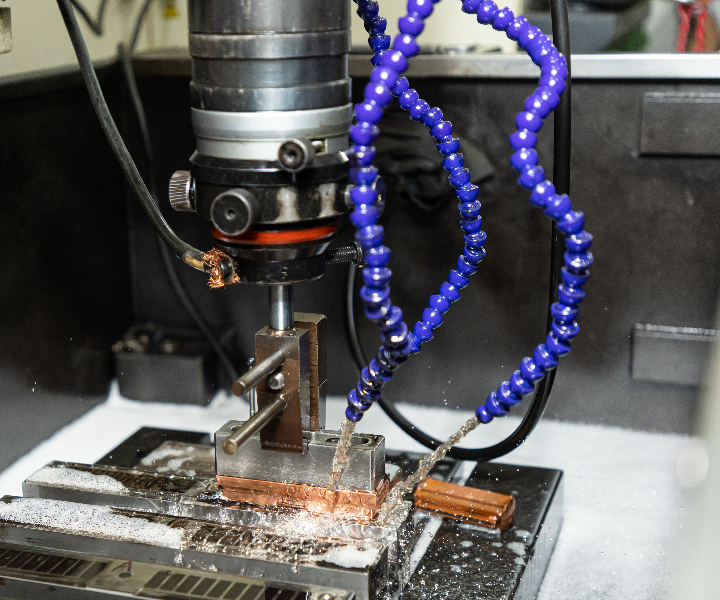

During the mold tooling process, we take the help of advanced plastic injection tools. CNC machining, EDM, and drilling as well as milling machines are in the facilities. The manufacturing workshop has experts for operating these machines.

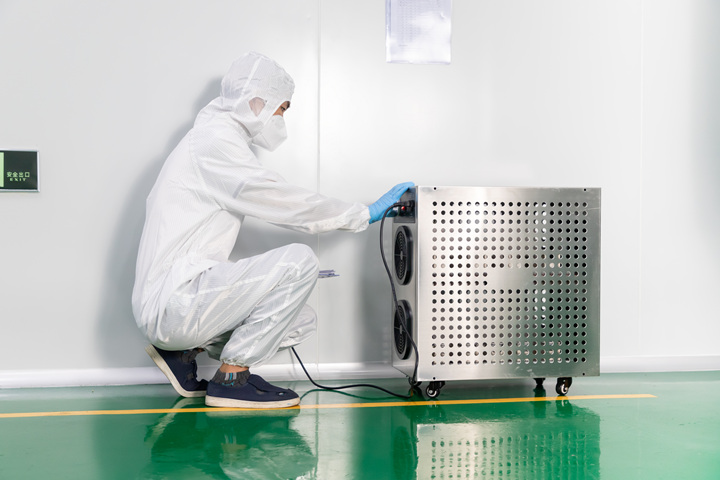

We have specialized in injection molding in a cleanroom for more than 10 years. Different clean room injection molding methods like micro injection, insert mold are available in Seasky and could meet industry requirements.

At first, the product is set through injection molding of the mold design. Prototyping a sample before inspection by the client is our standard practice. It goes to mass production only after the client gives it a thumbs up.

Our team has years of experience designing electronic devices and then creating prototypes before manufacturing the final output.

We are experts in plastic contract manufacturing and use years of knowledge to design and validate the production of different equipment with greater ease.

Our team delivers the highest quality components and equipment. This is only possible by picking great quality plastics used in electronic devices.

In the process of CNC machining, a wide variety of complex machinery is used to shape, cut and create the different prototypes.

Using various sterile injection molding including insert injection molding and micro mold plastics, We produce the required parts for clients by injecting quality molten materials.

Our team is experienced in ultrasonic welding plastic parts to hold two or more components together. The entire equipment is manufactured using this method to ensure the quality and integrity.

After a component of the electronic device is ready, Assembly and clean room packaging services are offered as per the specific needs of our clients.

Based on the specific needs of some of our clients, we offer pad printing and decorating services to ensure the best results.

We are a large-scale producer of electronic device contract components and hence, all our products are validated to ensure quality. .

As a leading electronic plastic contract manufacturer, we ensure timely distribution of products to our clients with the help of our multiple distribution channels.

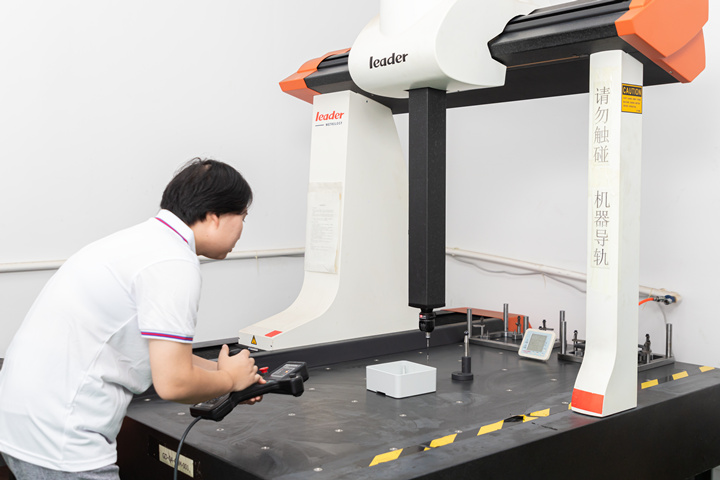

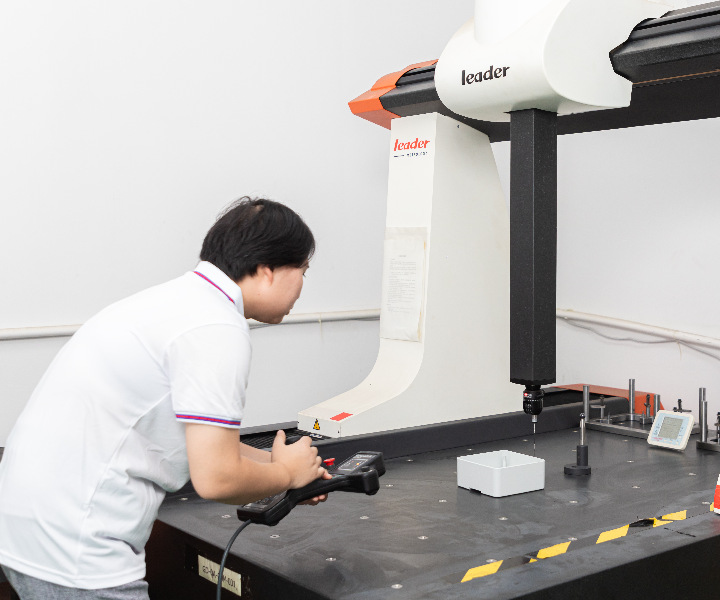

To ensure mold reliability, our molds are made of hardened steel, such as H13, S136, and 8407. Meanwhile, we are equipped with precision manufacturing and measuring equipment such as mirror spark machines, high-speed CNC, and CMM.

In the electronic industry, product quality cannot be compromised because it greatly affects safety. Seasky strictly follows ISO 13485:2016 quality management system and is certified by the third party.

As a professional mold manufacturing company, Seasky makes a flow analysis of the design to improve the functionality and suitability of the mold tooling.

We cooperate with more than 10 large raw material companies. Our raw materials come from the original factory, and we can provide a COC factory certificate. ISO10993 biocompatibility report is also available as customer request. In addition, we purchase color masterbatches that have passed certification from reliable suppliers for a long time.

…

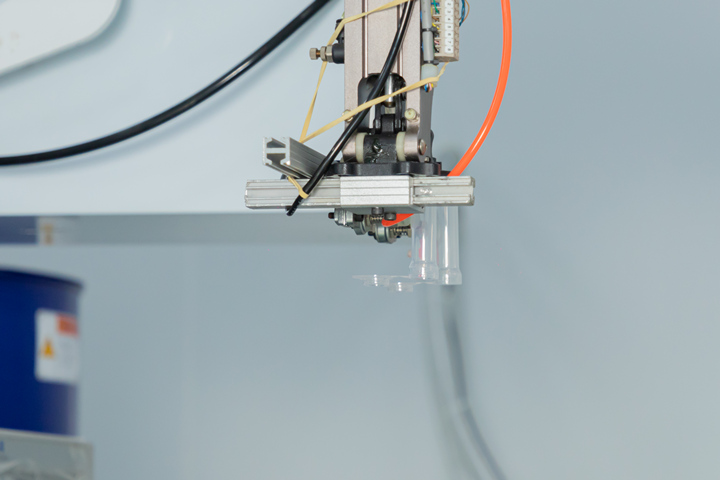

Dust-free manufacturing can reduce the environmental impact on products and improve product quality. Therefore, to maintain our cleanroom condition, we separate the material feeding and injection. Also, we apply automated equipment such as robotic arms, reducing personnel contact. Apart from that, we conduct daily disinfection for the cleanroom, as well as test and record the cleanliness twice a day.

Seasky is equipped with imported precision processing equipment and high-precision injection molding machines, such as Japan FANUC and Germany BOY. To ensure product quality and punctual delivery, we upgrade our equipment every 3-5 years.

The electronic field has a very high demand for product accuracy. Our workshops are equipped with advanced measuring instruments, such as a caliper, 10x-20x magnifier, 2.5D Vision Measuring Machine and Coordinate Measuring Machine. Utilizing these modern instruments, our inspectors control our product accuracy, meeting your tolerance requirements.