How SeaskyMedical Excels in Cryo Carrier Manufacturing

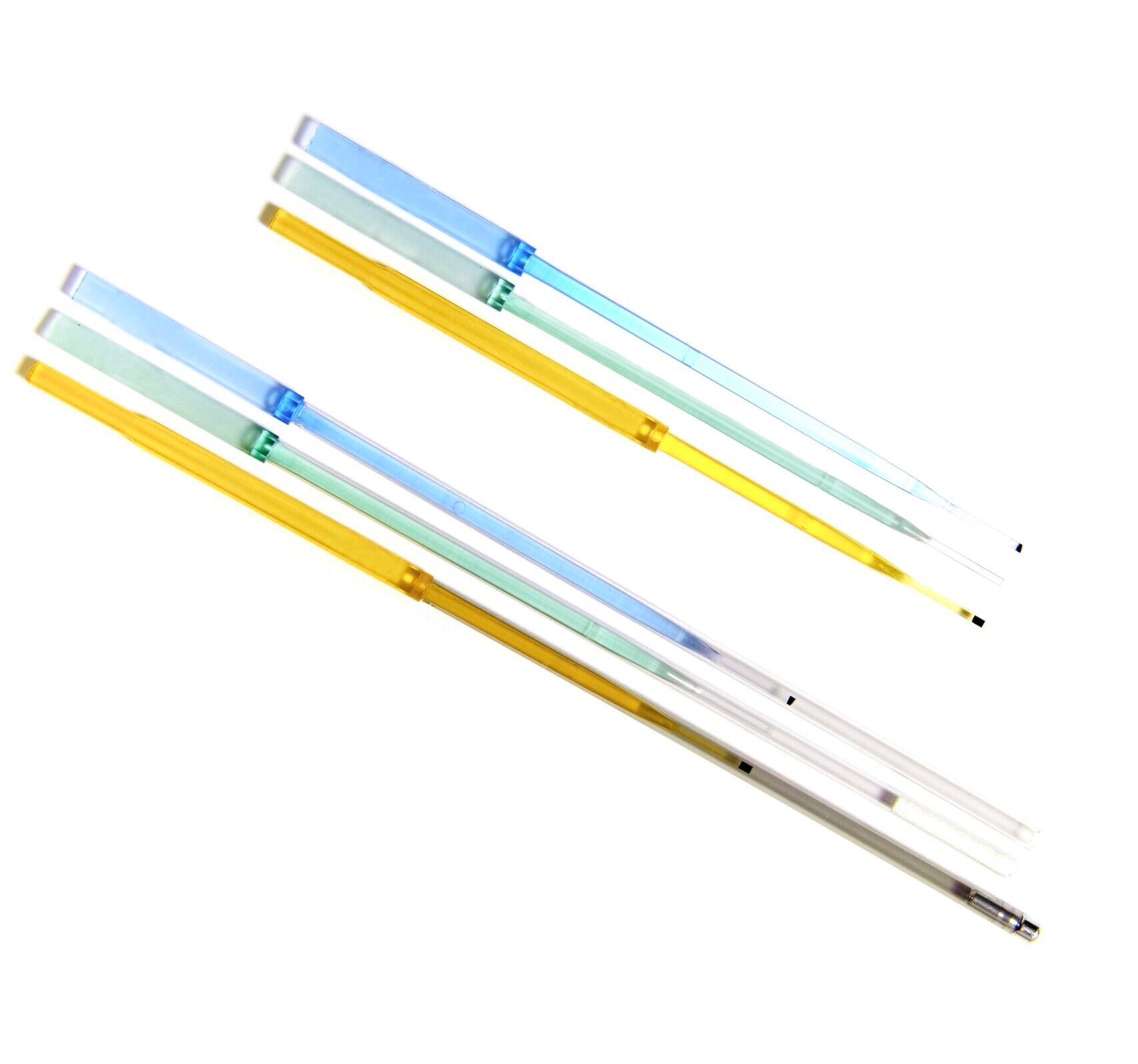

Trust SeaskyMedical‘s expertise to meet your market’s growing need for high-quality vitrification carrier rods. From creating highly detailed custom molds to meticulous inspections and testing, our streamlined manufacturing process establishes us as your reliable, one-stop shop that understands your requirements.

Parts & Mold Design

Our talented designers leverage their skills and experience to create tailor-made designs for parts and molds. A sample is manufactured for testing and quality control purposes, and a sample is sent to you for approval.

Prototyping

Using the latest tools and 3D printing equipment, we produce a functional prototype of the vitrification carrier rod. The prototype undergoes a series of inspections to ensure it meets global standards.

Plastic Injection Molding

Thanks to our state-of-the-art plastic injection molding machines, we can produce large volumes of vitrification carrier rods with maximum efficiency and precision while keeping production costs low.

Medical Validation and Verification

Each batch of vitrification carrier rods undergoes another round of medical validations and verifications upon completion to ensure compliance with industry standards. Upon request, we can send an inspection report detailing the results for your peace of mind.