Custom Medical Device Parts From Top Silicone & Rubber Molding Manufacturer

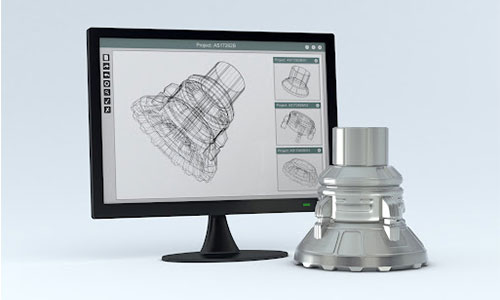

At SeaskyMedical, we choose LSR for designing and manufacturing medical silicone and rubber molded parts for a broad range of applications. If you’re looking for a brand that caters to high volume production while providing full-spectrum services from design to tooling, you can turn to us.