Medical Overmolding

Overmolding, an injection molding process of coating equipment with several materials, has circulated all manufacturing industries, especially the medical industry. This process is highly favored in the production of medical plastic products as it enhances better grip and ergonomics of devices, creates a waterproof seal, improves resistance to abrasion, dampens noise and vibration, provides electrical insulation, and many other benefits.

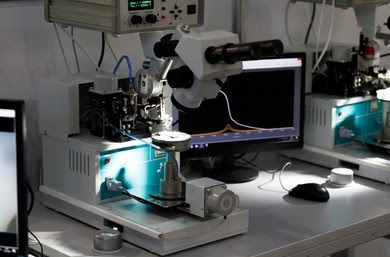

At SeaskyMedical, we overmold any kind of plastic medical device to improve the design, functionality and ease of operation. Following the stringent requirements for product cleanliness in the medical industry, we utilize our class 100,000 cleanroom in manufacturing and carrying out overmolding processes.