Our Custom Surgical Consumables Services

It includes medical equipment assembly, surgical instruments, and implants vital in the modern healthcare system.

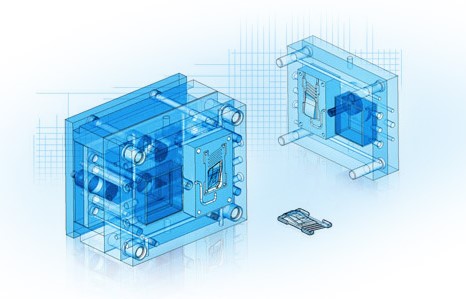

As a medical plastic injection molding company, we are able to produce all kinds of plastic surgical disposables. We don’t have surgical consumables in stock, carrying out injection molding of plastic surgical products after accepting your order.

In medical establishments, surgical consumables are the most commonly used supplies for single use. Since the use of plastic in healthcare industry is continuously increasing, many industries are engaging in surgical disposable items production. Based in China, SeaskyMedical is the most reputable manufacturer of high-quality and affordable surgical disposable products.

From syringes to suction catheters, drug test disposables, TMP “Y” Connectors, plastic mouth piece, Supplemental Lines, 3 Way Stop Cock, SeaskyMedical manufactures the best surgical consumables for infection control.

It includes medical equipment assembly, surgical instruments, and implants vital in the modern healthcare system.

SeaskyMedical specializes in the production of disposable surgical supplies for the medical industry. It is one of the recognized industry surgical consumables manufacturers for its dedication to the quality of all its surgical consumable items, using a wealth of expertise.

Surgical disposable items require high precise tolerance, top surgical disposable manufacturers are able to provide free mold tool design and injection mold making for high performance, low cost, and convenience to the healthcare industry.

Chromatography resins and columns is a widely used and trusted method for sample separation in the healthcare industry. That is why we offer a selection of resins for separation via affinity, size exclusion, hydrophobic interaction, ion exchange, hydroxyapatite and fluorapatite.

With the help of automated, high-speed cutting tools, experienced surgical disposable manufacturers use CNC Plastic Machining to produce surgical items. It enables to produce bulks of disposable surgical supplies in short time.

We produce surgical disposable product in a clean room to reduce the risk of contamination. Clean room injection molding is suitable for the medical, pharmaceutical, and biotech industries that frequently create parts in a cleanroom environment.

For creating quality surgical disposables for the medical industry, we use secondary operation services that include assembly, shielding, engraving, printing, sterile packaging, and shipping the item directly to clients..

Single-use surgical disposable items manufactured by SeaskyMedical are individually wrapped and used for one patient during a single procedure. It ensures the safety of patients by limiting their exposure to contaminated devices while offering greater cost-effectiveness.

Besides creating bodily implants, the CNC machining at SeaskyMedicals can create surgical and medical supplies. These machines are suitable to deliver high tolerance through cutting, including milling, turning, drilling and grinding.

Our single-use microsurgical medical disposables are widely used in the medical industry to save time and reduce healthcare-associated costs. Micro surgical disposable product could also be manufactured by Seaskymdecial.

The medical consumables produced by SeaskyMedicals are available in many designs for the surgical environment. Since they are usually disposable, they are not used on or by more than one person.

Medical and surgical items are suitable for treating or diagnosing a patient’s illness, injury, or condition. That’s why we aim to manufacture high-quality medical consumables for the hospital or surgical environment.

We allow high production capacity of the medical and surgical consumables at SeaskyMedicals. It includes all aspects of the fabrication of a device, from designing a manufacturing process to scaling-up to ongoing process improvements.

SeaskyMedical prides itself in manufacturing low-risk injection molding solutions for the medical sector. For over ten years, we have engaged in precision mold making and injection molding. It has helped us produce quality operating room consumables for the diversifying needs of the medical industry.

As one of the reliable surgical disposables suppliers, Seaskymedical provides one-stop service for our clients, helping them to reduce cost and time, and get their trust.

Medical devices are the fundamental component of the healthcare system. If they are of good quality, they help prevent, diagnose, treat, and rehabilitate illness and diseases safely and effectively. If you are looking for a trustable surgical consumables manufacturers, you can always turn to SeaskyMedical, because we offer:

The value-added services at prominent surgical disposables suppliers provide you with an array of choices. It includes medical device assembly and packaging in clean room, pad printing, medical welding and other options.

The surgical consumables at SeaskyMedical are produced using efficient and cost-effective methods. We use high precision, accuracy, and quality in an ISO 8 cleanroom. Further, we have also gone through the rigorous ISO certification process.

Medical materials used in manufacturing surgical disposable are chosen from chromatography resins and columns. Biocompatibility, strength and resistance of materials are consider from reliable surgical supply manufacturers.

SeaskyMedical is an expert in producing surgical consumables and providing low-risk solutions. By utilizing ten cutting-edge advanced injection molding machines made in Germany and Japan, we strive to provide professional and all-inclusive support at all the stages of medical product development.

Our medical plastic injection capabilities include micro, overmold, insert injection molding. Having an experience of more than 11 years in project management and supply chain management, we strive to meet the diverse needs of the medical field.

We are well aware that the surgical disposable product we produce directly affect the health and safety of the users. That’s why we always keep safety, quality, and cost in mind. We aim to become your one-stop service for obtaining quality surgical consumables at competitive prices.

SeaskyMedical serves customers with medical injection molding solutions from mold toolin gdesign and manufacturing. Our custom solutions include ISO 8 clean room contract manufacturing, robust expertise, advanced cutting-edge molding machines, and quick response time.

To streamline the manufacturing surgical consumable processes, we have come up with a common language by using quality measurement techniques. It has helped us eliminate barriers to produce a smooth and quick problem-solving method.

At SeaskyMedicals, we strive to reduce the manufacturing lead time by automating inventory management, informing our medical plastic injection molding suppliers about the sales data, having a clear lead time contract, and allowing you to order smaller amounts more frequently.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.