2K Injection Molding Service

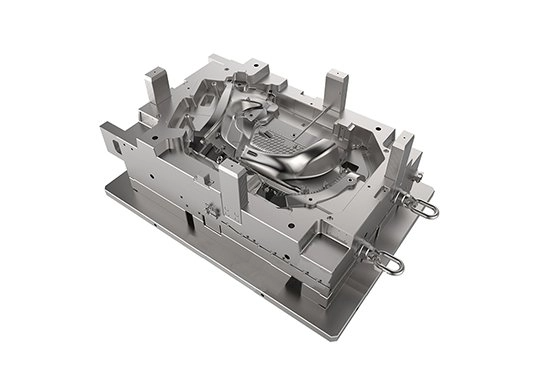

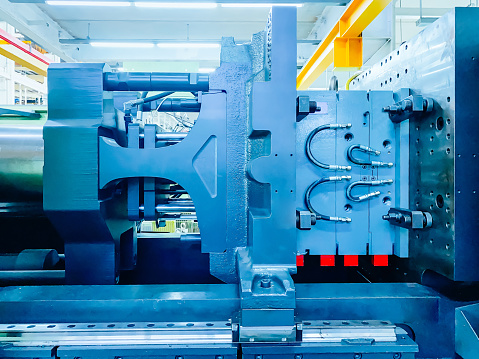

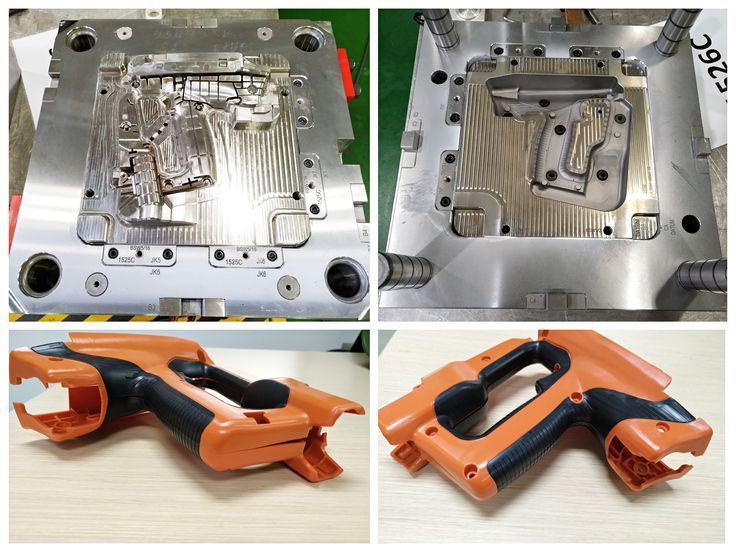

2k injection molding is also known as 2-shot injection molding or double-shot injection molding. It is a manufacturing procedure of molding two separate substances or colors into a single plastic item. By utilizing a 2k injection molding machine, this plastic molding technology combines two substances or two distinct colors into a single finished plastic object.

To create flawless final products, 2K injection molding combines two distinct materials, such as hard and soft substances. The foremost substance that was injected is known as the base material, and the second material that was injected is known as the overlay material. SeaskyMedical is a top-class plastic injection molding company, and we offer a one-stop 2k injection mold service.