How Does ISO 13485 Certification Influence Supplier Selection?

ISO 13485 certification influences supplier selection by redefining …

SeaskyMedical focuses on the development and production of medical injection molded products. We assisting you in all stages, including product design and development, mold design and building, material selection and injection molding.

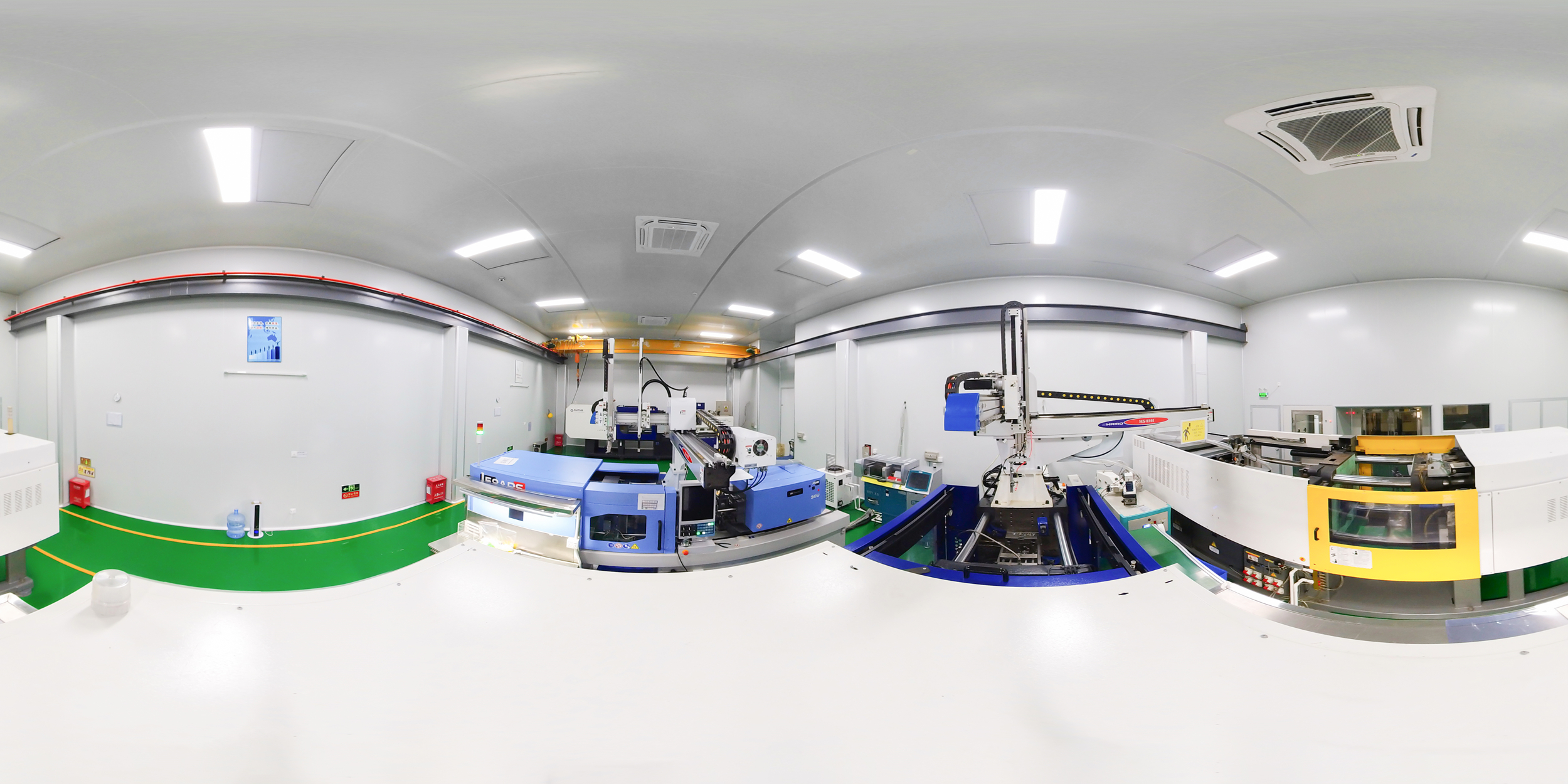

Seaskymedical is an ISO-certified medical injection molding company that manufactures injection molded plastic devices that are used in the medical industry. We make use of certified raw materials and carry out the production, assembly, and packaging processes in our ISO 8 cleanroom using reliable injection molding machines. Afterwards, they are put through stringent inspection to ensure that they meet the industry standards.

At Seaskymedical, we assist in providing you with excellent medical injection molding solutions for a wide array of medical products.

As a professional injection molding company in the medical field, SeaskyMedical provides our customers with comprehensive services and support.

In addition to being a certified medical injection molding company, we have in-house experts and cutting-edge machines that improve the production of your medical injection molded products. Our capabilities extend to all forms and stages of medical plastic molding manufacturing, including product design and development, material selection, mold making, injection molding, and secondary operations.

SeaskyMedical has rich material knowledge and can deal with a wide range of medical-grade plastics. Also, with our ISO 13485:2016 certified cleanroom and micro injection molding capability, we can meet the stringent cleanliness criteria and tight tolerance of the medical field.

The medical industry has extremely high requirements for product production. To minimize the environment impact on products and improve product quality, it is very necessary to manufacture in a dust-free workshop. SeaskyMedical invests and establishs our own ISO 8 cleanroom, which has passed the ISO 13485 certification.

The demand for micro-injection molding products in the medical field is growing rapidly. SeaskyMedical addresses your needs with excellent micro injection molding capability. We have imported medical micro injection equipment, specializing in the production of micro products ranging from 0.1g to 0.5g. As well as that, our product wall thickness can be as thin as 0.2mm.

Seaskymedical has extensive expertise with medical insert molding used in making a plastic embodiment for metal and fragile medical devices that need better grip. With this, your hands will maintain a perfect grip on them no matter the condition they are exposed to.

Overmolding, an injection molding process of coating equipment with several materials, is very popular in the medical industry. For better rigidity and toughness of plastic medical devices, we carry out overmolding processes. Your plastic medical devices will be more robust and there will be no need for glue.

Seaskymedical is an all-in-one medical molding company. We are capable of handling all your medical plastic injection molding projects

starting from the design & development all the way to the secondary operation, assembly, and packaging.

All the necessary tools needed to make your custom mold are available. Also, we have specialized experts who are proficient in fabricating the right mold for your needs.

We provide you with 3D prototypes, allowing you to check while we make the necessary corrections until you are satisfied.

The plastic injection molding is carried out, ensuring that we fulfill your order using the approved prototype and following the agreed lead time.

We offer various secondary operations including machining, ultrasonic cleaning, liquid filling and sealing, as well as shrink-wrapping

Seaskymedical is highly-rated among the medical device injection molding companies for manufacturing custom injection molded products used in the medical and pharmaceutical field. We complete your bulk order of plastic medical molded products efficiently, and are able to meet the strict regulatory guidelines that medical applications require.

As a professional medical molding company, we provide our customers with comprehensive services and support in manufacturing their medical devices, as well as meeting the strict cleanliness standard and tight tolerance of the medical field.

Below are a few of the reasons why you should choose us as your medical molding manufacturer amongst other medical molding companies.

Thanks to our experienced workforce, we’ve been in operation for over a decade, satisfying the exact needs of both small and big medical institutions. You can trust us to fulfill your medical injection molding projects according to your specifications.

To ensure optimal cleanliness and safety of our products, all manufacturing processes, including assembly and packaging are carried out in our class 7 & 8 cleanroom.

We have ISO 13485:2016 certificate, guaranteeing the safety and reliability of our products. All our productions are done in compliance with the regulatory standards in the medical industry.

Our customers enjoy quick delivery time as we make use of advanced injection molding machines to fasten and strengthen production processes. Also, we have a professional manufacturing team that ensures that customers receive their order within a short lead time.

In the medical field, product quality represents its safety in use. SeaskyMedical always keep this in mind. We follows the quality management system for international medical device manufacturers, and have been certified by ISO 13485:2016.

Gain in-depth related knowledge through our blogs. Or view our cases and see how we solve problems with robust injection molding capabilities.

ISO 13485 certification influences supplier selection by redefining …

Medical molded parts operate within a regulated framework …

Material traceability in medical injection molding is not …

The medical equipment itself has strict precision properties. …

96 deep well plate is one of IVD …

Lure tapper is a standardized micro permeable joint …

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.