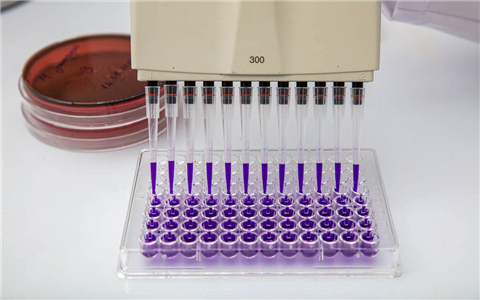

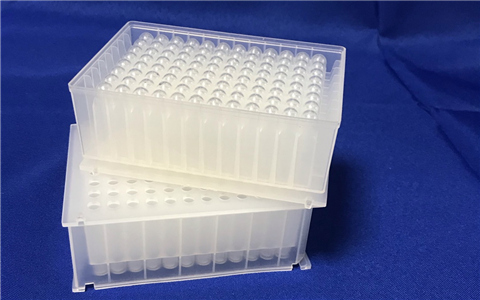

96 deep well plate is one of IVD component which is made with PP resin by using plastic injection molding.

Although the customary strategies for developing molds perform well, in 96 deep well plate mold it still require specific development expertise. It is deep holes and ribs and it is tight tolerance.

Challenge

Also 96 deep well plate mold manufacturing has unique specification profiles as usual medical injection mold. It is like short cycle times, multiple mold cavities, highly polished, refined surfaces, complex hot runner technology and automation systems.

In addition to you should consider low unit cost and low scrap rate, high precision, high energy efficiency and high output.This situation forces molding company to maintain a balance between technical feasibility, high process reliability, complex mold technology, and economic efficiency.

If it is first time to design and manufacture, it is easy to have the 96 deep well plate stick on core side and cavity side. It is lack consideration for ejection force and sticking force. It is quite common for new guys to face this problem.

In additional lack of cooling and unreasonable cooling will scrape the project too.

Solution

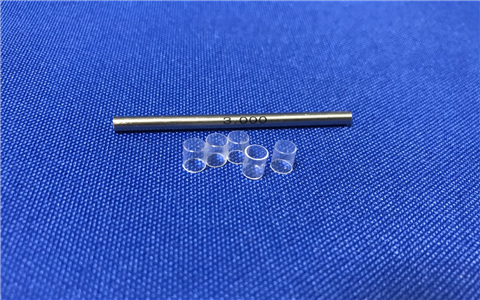

SeaskyMedical specilize in 96 deep well plate plastic mold manufacture and molding. Also we are experience of different IVD disposable plastic molding such as pipette tips, samples and reaction tube, cuvettes and microcentrifuge tube,petridishes, cell culture dishes, trays, PCR plate, microtiter plates, racks and boxes etc.

Our mold designer and molding engineer with more than 10 years experience for medical mold and molding.