Overview

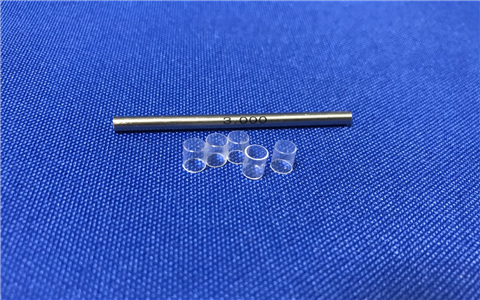

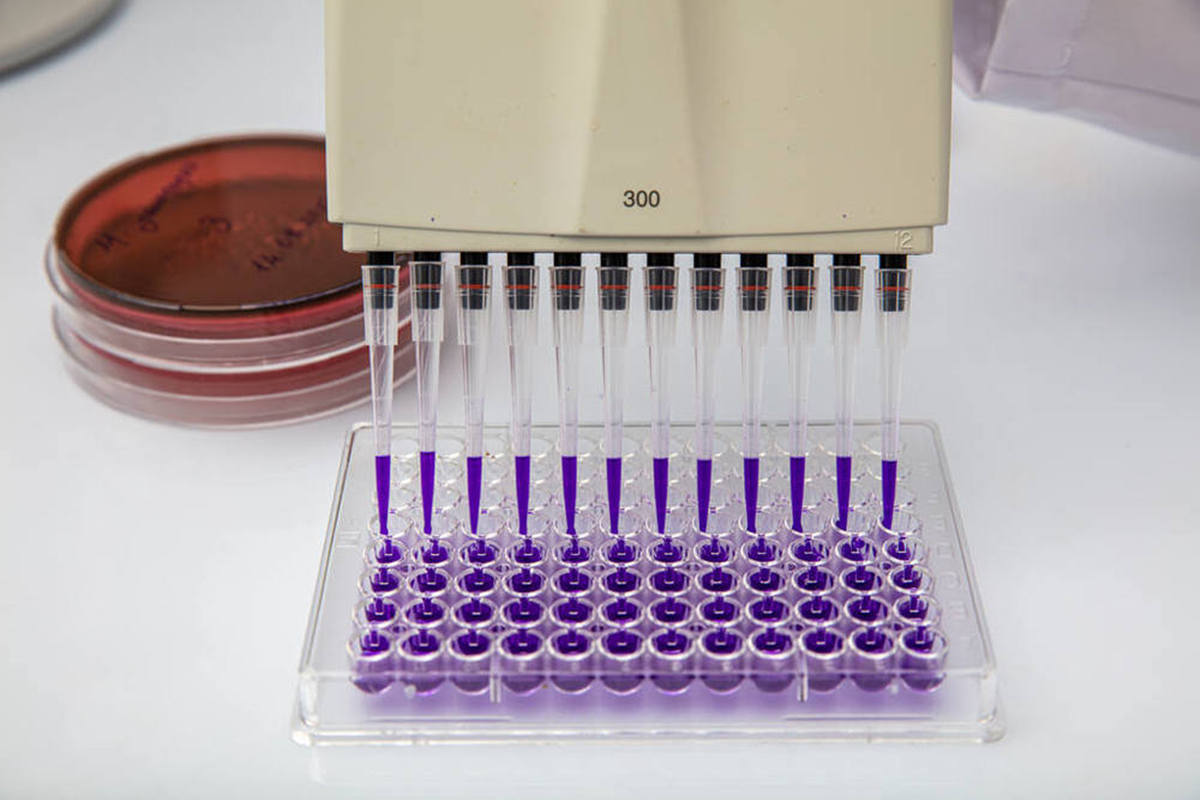

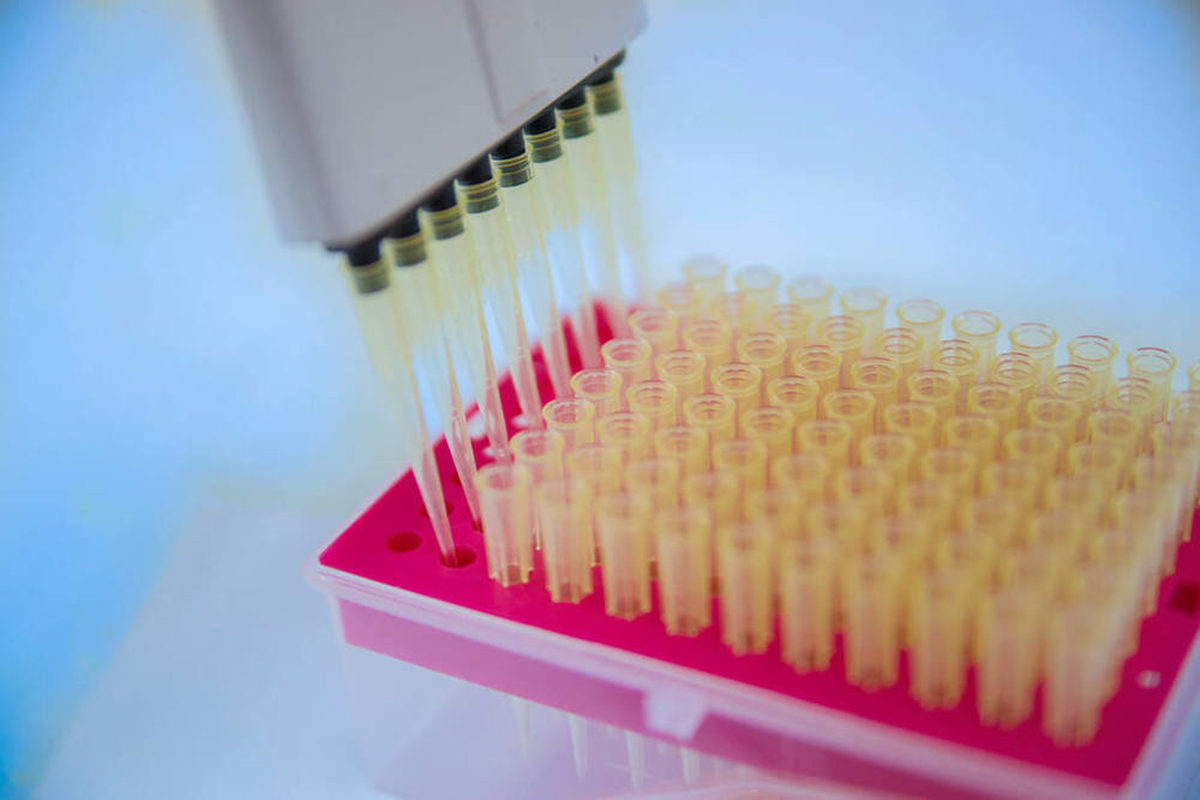

Pipette tip demand is very huge for medical plastic market. We do both precise pipetting suction head mold and plastic molding. The max. cavity we made now is 64 cavity injection mold, it is ,6000,000pcs capacity molding on our FAUNC 150T injection machine, the mold can be injected on 50T JSW injection machine too. The end hole of pipetting suction head tolerance is +/-0.02mm. You can review below video for pipette tip injection molding production.

Challenge

Generally pipette tip injection mold is multiple cavity mold and short cycle to assure the production capacity. It is more than 16 cavity mold, also you should assure all of the cavity is consistence tolerance. In the meanwhile, you should make sure the mold is molding in short cycle and stable. If it cold runner mold, during the high speed injection, it is easy to crash the pipette tip mold. You should reduce the cycle step by step. Also you should prevent plastic silk from the runner or somewhere in the mold to prevent crash.

Our Solution

With precise injection mold making, optimized mold concept and electronic injection machine, we can assure the quality and production capacity. For the pipette tip mold, there is two mold concept. One of them is hot runner switch to cold runner, the other side hot tip runner mold. If there is huge production you can use side hot tip mold, it is hot tip to pipette tip side direct, it save resin and higher productivity, if so the cooling for the pipette tip is very important.

For the pipette tip resin, we have lots of project to use this kind of medical resin, we can save the lead time for your production.