Why Seaskymedical Over Other CNC Mold Companies?

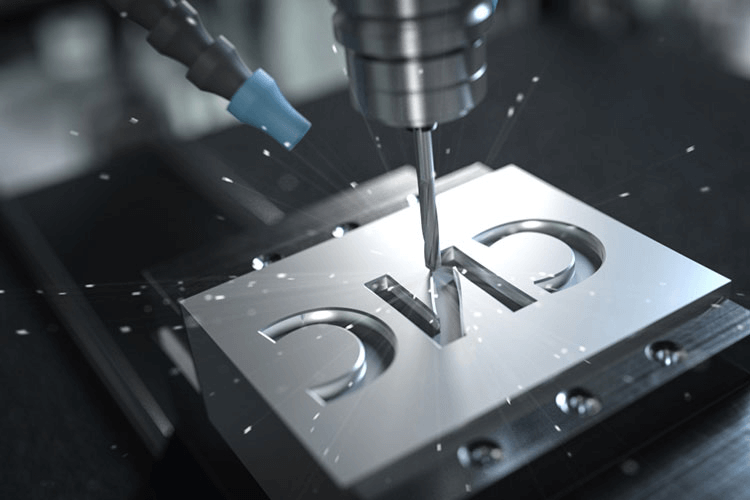

Many CNC mold companies are out there, but what makes us stand out is our custom finish, rapid turnout, and scalability. Our company uses the latest technology to deliver high-end products in less time.

Through our trusted network of suppliers, we deliver specialized CNC mold making services to our customers. Our highly skilled CNC molding machine shops are capable of producing any unique mold tooling design, no matter how basic or complicated. We provide speedy CNC prototypes, small-batch machining, and high-volume manufacturing services.