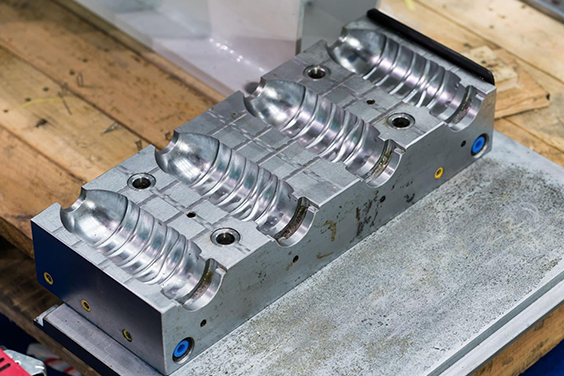

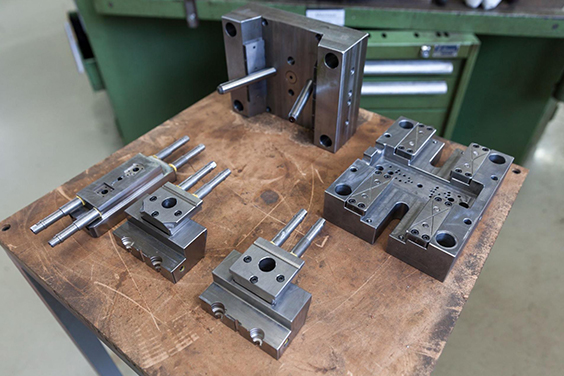

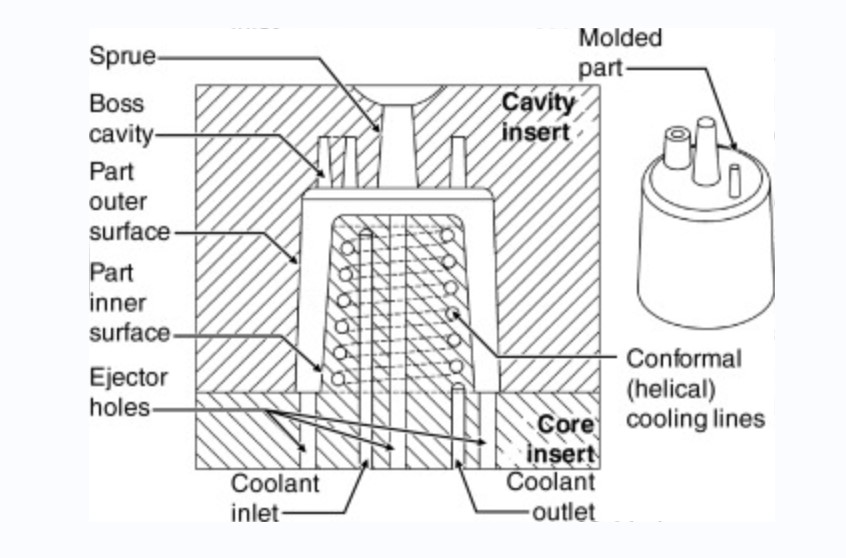

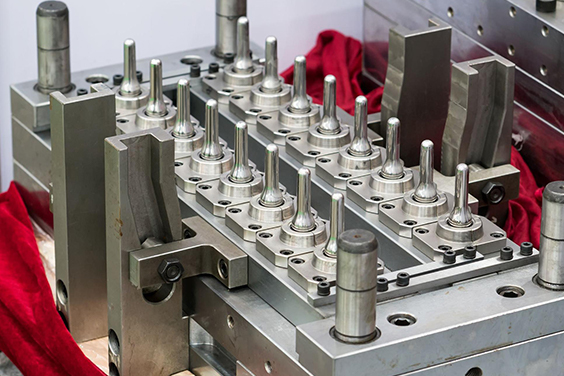

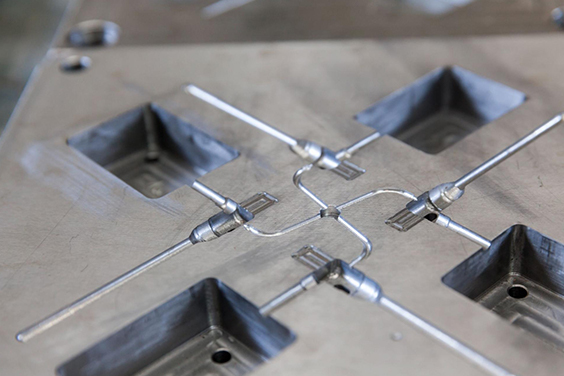

Various Insert Molding Solutions

for Your Medical Need

The insert molding applications depend on the client’s requirements and the standard size guidelines. We offer a number of materials used for insert injection molding, along with other ranges of our services.