Our Capability of 3D Rapid Prototyping Applications in the Medical Industry

Seaskymedical has a remarkable capacity in the manufacturing of complex medical product prototypes and fabrication of medical devices, surgical instrument prototypes, and medical implant components. We have a large range of attributes that make our medical 3D printing service the best in the industry. Here are the things that we can do for our customers:

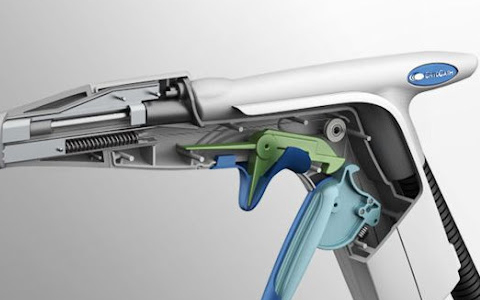

Class I ABS Handles for Surgical Instruments

In order to meet the demands of the highly exacting medical industry, Seaskymedical uses ABS thermoplastics to produce high quality reusable handpieces. We produce a wide spectrum of handpieces to meet different sizes, shapes, and purposes. Features such as high temperature resistance, good durability, and color retention also can be added to your handle specifications.

Class II

We will be glad to provide you with affordable Class II medical devices that are CE marked and ISO 13485 certified. Our engineers will be glad to assist you in the design and development of the right product for your industry. Our quality assurance and quality control measures have been tested and approved by various health agencies including the U.S. Food and Drug Administration (FDA).

Class III

Seaskymedical can provide you with the best full-service solutions for any medical device that is Class III. Our engineers will assist you in the design and development of the best product for your business. If you need to meet the requirements of FDA, we can assist you in meeting the criteria. During the design process we will work with you to ensure that any product we create is safe, reliable, and accurate.

Prostheses and Implants

Seaskymedical is capable of producing high quality prostheses and medical implants. Any custom surgical procedure can be handled by our team of engineers. The quality of our 3D printed prototypes and finished products will exceed your expectations and our record of customer relationships is unsurpassed.

Rubber Prototyping

Seaskymedical has a wide range of capabilities when it comes to rubber prototyping. We provide you with high quality rubber products that are 100% reusable. We provide all the 3D printing and finishing services necessary to complete your rubber prototypes to the highest standards.

Medical Silicone Prototypes

Unlike rubber, the high quality silicone prototypes that Seaskymedical produces can be sterilized and reused many times. We produce a wide range of prototypes in different sizes, shapes, and colors to ensure that you get the right product. We will be glad to provide you with the best silicone prototypes and implants for your medical applications.

A few of common applications include:

- Prosthetic

- Implantable prototypes

- Medical Device Enclosures and housings

- Wearables

- Handheld devices

- Medical diagnosis equipment

- Ventilators

- Medical monitor instruments

- Anatomical models

- Ultrasonic equipment

- Physiotherapy apparatuses

- MRI devices

- X-Ray equipment

- Clinical analytical instruments

- Care equipment