Our Custom IVF Consumables Services

The experts at SeaskyMedical help bring your ideas for bespoke IVF consumables to reality through an assortment of customization options.

Trust the expertise of SeaskyMedical as a seasoned medical supply manufacturer to produce various plastic injection molded IVF consumables made at the time of order.

IVF disposables play a crucial role in different aspects of fertility treatment, whether for extracting genetic materials or preserving them for future use. With the industry seeing more demand for injection molded plastic IVF disposables, SeaskyMedical stands out as a professional manufacturer that caters to your market’s needs.

Backed by more than a decade of experience in plastic injection molding, we leverage our skills, advanced machinery, and industry knowledge to create reliable IVF disposables. We produce IVF syringes, cryovials, and ICSI dishes that meet global quality and medical industry benchmarks.

The experts at SeaskyMedical help bring your ideas for bespoke IVF consumables to reality through an assortment of customization options.

The overall design of every IVF consumable product can be modified according to your market’s preferences. Seasoned designers leverage their skills and experience to develop the design, implementing adjustments to enhance their performance.

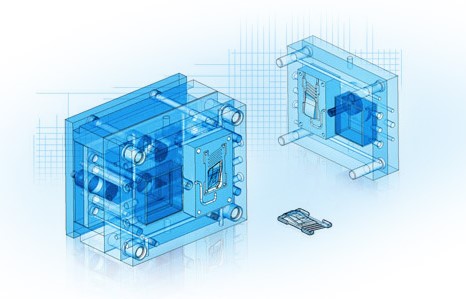

Along with creating designs for the IVF consumables, we can also develop plastic injection molds that will be used in the manufacturing process. Our expertise in the field ensures the molds have tight tolerances, resulting in consistent output at lower costs.

Choose from our selection of high-grade plastic raw materials sourced from suppliers we have long-term relationships. We carry a range of PP, PS, and PE that go through the same quality control standards as our injection molded IVF consumables, ensuring consistency throughout.

Utilizing the latest CNC machines available in the market, we manufacture and refine the IVF disposables to further elevate their distinct qualities. Our time-honed process allows us to complete bulk orders within a short lead time without compromising quality and durability.

All our IVF disposables are manufactured in a Class 7 cleanroom designed and maintained according to industry standards. With little to no contact with dust particles, our plastic injection molded products won’t contaminate or adversely affect the sensitive genetic materials they come into contact with.

From full assembly to printing and engraving labels on the IVF disposables, we have dedicated precision equipment to take on the task. We also handle packing the medical supplies in sterile packaging to preserve their sterility and protect them from external contaminants.

We wrap all our plastic injection molded IVF disposables in sanitized packaging individually, preserving the sterility of each product and reducing the risk of contamination. This also makes them easy to store and use per patient, limiting material waste.

Thanks to the precision manufacturing techniques and advanced machinery we use, our plastic injection molded IVF disposables have the tightest tolerances and precise dimensional accuracy. Our commitment to excellence guarantees the optimal performance of our IVF disposables with minimal leakage or dead spots.

With micro manufacturing implemented in crafting our IVF disposables, we can maintain the accurate measurements of all parts, even the tiniest ones. This makes assembly faster and utilization more precise, reducing waste and errors.

We offer a wide range of designs for each IVF disposable we produce, providing you with various options and expanding your product lineup. These designs are also easily modifiable, opening the door for more plastic injection molded products that address diverse market demands.

Quality is the highest priority at SeaskyMedical, and this is clearly exemplified in how we handle our production process. Strict quality control is implemented in every production step, making sure they meet our established benchmarks with no deviation.

Heavy investment in the latest manufacturing equipment and streamlining our processes allows us to accommodate large volumes of IVF disposables. This translates to consistent output and shorter lead times without compromising quality and structural integrity.

Since opening our doors in 2015, SeaskyMedical has been laser-focused on manufacturing world-class IVF disposables for the global market. We’ve also inherited over 11 years of experience in production and supply chain management from our parent company, further elevating our manufacturing expertise. This, combined with our commitment to excellence and heavy investment in advanced machinery, makes us the preferred choice for medical supply brands around the world.

With the great role IVF disposables play in reproductive medicine and fertility treatment procedures, medical supply brands must provide their market with injection molded products that meet their needs. No other manufacturer does it better than SeaskyMedical, and here’s why:

More than product manufacturing, we also offer a range of services to make your sourcing experience as smooth and seamless as possible. From comprehensive consultation and custom design to product packaging and after-sales, our team is always ready to accommodate your demands.

In the medical industry, cleanliness is tantamount to success in every fertilization treatment. Understanding this, we manage ISO 8 cleanrooms where we manufacture and wrap the IVF disposables. With no dust particles in the air, our disposables maintain their pristine condition.

All raw materials we use in crafting IVF disposables are chosen from chromatography resins sourced from long-term material suppliers. This guarantees the optimal performance of our disposables while reducing the risk of contamination or negative effects on the genetic materials.

Along with in-depth material sourcing, we also heavily invest in the latest plastic injection molding machines from Germany and Japan. By using these machines in our manufacturing processes, we can ensure the precision production of each IVF disposable that leaves our facility.

SeaskyMedical’s craftsmanship expertise knows no bounds, implementing various production techniques in creating IVF disposables according to your prescribed requirements. Complemented by our robust project management and supply chain experience, we’re sure to meet your market’s demand for diverse IVF disposables.

We constantly strive to maintain a balance between quality and cost, as we understand the value of profit while offering premium products. Our processes ensure consistent quality and output in every IVF disposable purchase without exceeding your available budget.

As the reproductive medicine and fertility treatment industry continues to evolve, medical supply businesses must also adapt to the changing market trends. SeaskyMedical meets you there by offering various customization options, allowing you to stock up on disposables that address your market’s diverse demands.

We’ve honed our manufacturing process over the years, streamlining the production steps while maintaining the quality customers expect from us. We also implement advanced techniques and listen to your requirements, taking note of all your demands before beginning each project.

Combining innovative manufacturing processes and streamlined workflows allows us to complete large volume orders in a short timeframe. Plus, you’re given constant updates throughout the process, so we can address your concerns as soon as we see them.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.

Seasky Medical serves you with medical injection molding solutions from design to tooling to material selection and manufacturing. Contact our specialized team and solve your problem now.