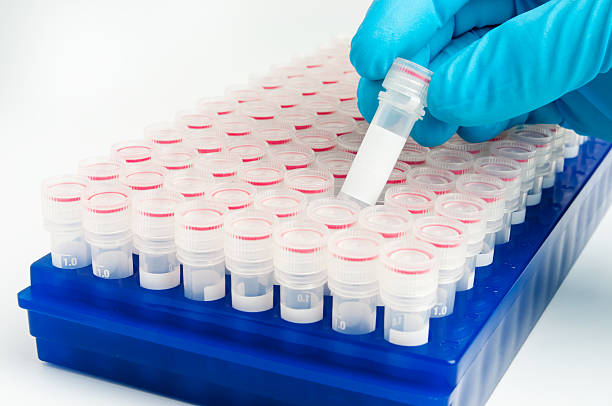

OEM/ODM Cryogenic Vials Made to Perfection

Witness SeaskyMedical expertise in manufacturing plastic injection molded medical supplies and providing the global market with reliable cryovials. Through decade-long production experience and robust injection molding know-how, we’re capable of meeting your specific demands with remarkable precision.

Parts & Mold Design

Every project starts with the creation of molds for the cryovial parts and molds. Our expert team drafts the designs based on your expressed requirements, leveraging their years of experience and well-developed talents.

Prototyping

After completing the mold and part design, we proceed to create functional cryovial prototypes, continuously refining them until we get the desired results. We then send you a sample for review, making changes according to your recommendations.

Bulk Manufacturing

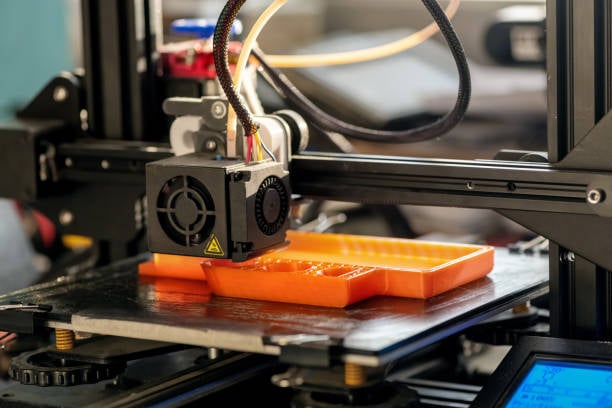

Once you approve the prototype, we will then mass-produce the cryovials using our state-of-the-art plastic injection molding production lines. We conduct routine inspections after each step, ensuring the cryovials meet our manufacturing benchmarks.

Product Testing

Upon completion of the cryovial production, they go through a series of reviews and testing to guarantee they comply with international standards. We also take extra steps to verify the capabilities of our cryovials, with inspection reports kept and ready for sending upon request.