Streamlined Plastic Injection Molding by Industry Professionals

SeaskyMedical superior plastic injection molding manufacturing capabilities are the result of a decade-long experience in the industry. Through continuous refinement and dedication to excellence, we’ve streamlined the process while maintaining the same quality and consistency we’re known for.

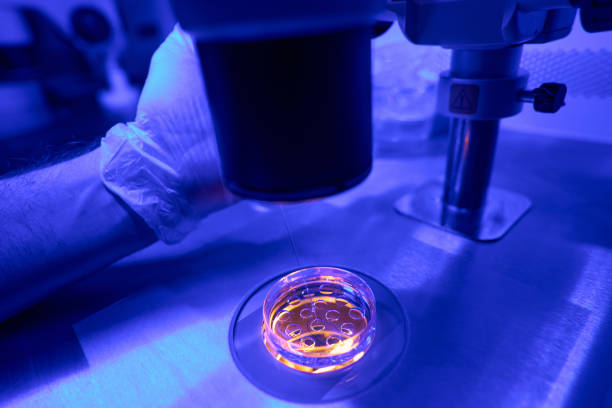

Parts & Mold Design

We begin projects by creating the part and mold design for the ICSI culture dishes. Expert designers take your input during consultation to craft bespoke designs, which are tested and examined before completion.

Prototyping

The designs are then turned into functional samples through prototyping, where our engineering team continues to work on them until we get the desired results. A sample is then created and sent to you for review and approval.

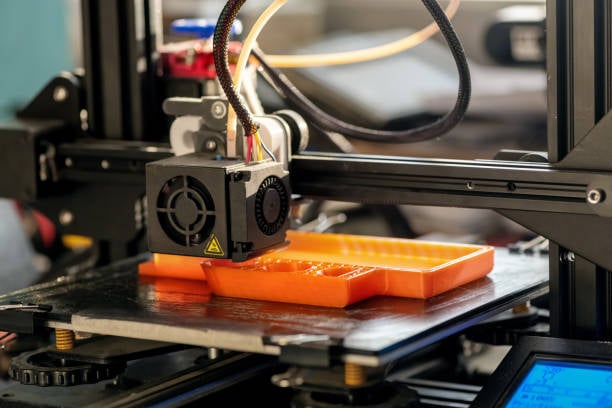

Plastic Injection Molding

Once we receive your confirmation, we proceed to mass production of the ICSI culture dishes. We utilize our modern production lines equipped with the latest plastic injection molding machines for smooth and continuous operation.

Product Testing

The final step of our manufacturing process involves a series of inspections and tests to validate the quality and performance of our ICSI dishes. We can also provide you with an inspection report upon request, further boosting your confidence in our brand.