In the world of medical devices, controlling the flow of fluids is often a matter of safety and precision. Whether delivering medicine, drawing blood, or monitoring pressure, doctors and nurses need a simple, reliable way to direct liquids from one place to another. This is where the stopcock comes in.

A stopcock is essentially a manual valve for medical tubing. It is a small, plastic device that lets a clinician open, close, or redirect fluid pathways with a simple turn of a handle. From basic two port valves to complex multi port manifolds, stopcocks are vital components in countless procedures.

For medical device engineers and manufacturers, understanding stopcocks is key to designing effective fluid management systems. This blog will explain how they work, the different types available, and why their reliable performance depends on high precision injection molding.

How Does a Stopcock Work?

The basic design is elegant in its simplicity. A standard stopcock has three main parts molded from medical grade plastic:

- The Body: This is the main housing with several ports (openings). These ports have luer lock connections, allowing them to be securely attached to syringes, IV lines, or monitors.

- The Core or Rotor: This is a rotating plug inside the body. It has one or more internal channels machined through it.

- The Handle: Attached to the core, this lever shows the user which way the internal channels are pointing.

By turning the handle, the user rotates the internal core. This aligns its channels with different ports on the body, opening or closing specific pathways. The tight fit between the core and the body prevents leaks. A good stopcock turns smoothly, clicks firmly into position, and provides a clear visual indication of the flow path.

Types of Medical Stopcocks: From Simple to Complex

Stopcocks are categorized by the number of ports and how many fluid pathways they can control.

The 2-Way Stopcock (Luer Lock)

This is the simplest and most common type. It typically has two ports.

- How it works: The handle has two positions: ON and OFF. In the ON position, the internal channel creates an open path between the two ports, allowing fluid to flow. In the OFF position, the channel is turned away, blocking the flow completely.

- Common use: It acts as an on/off switch in an IV line. For example, it can be used to pause an infusion without disconnecting the tubing.

The 3-Way Stopcock

This is the workhorse of many clinical settings. It has three ports arranged in a T shape or a Y shape.

- How it works: The internal L-shaped channel can be rotated to connect any two ports at a time, while blocking the third. This allows the user to control which line is open to the patient.

- Common use: A classic use is with a pressure monitor. One port connects to the patient’s arterial line, one to the saline flush syringe, and one to the pressure transducer. By turning the handle, the nurse can either monitor the patient’s pressure or flush the line with saline, all without disconnecting anything.

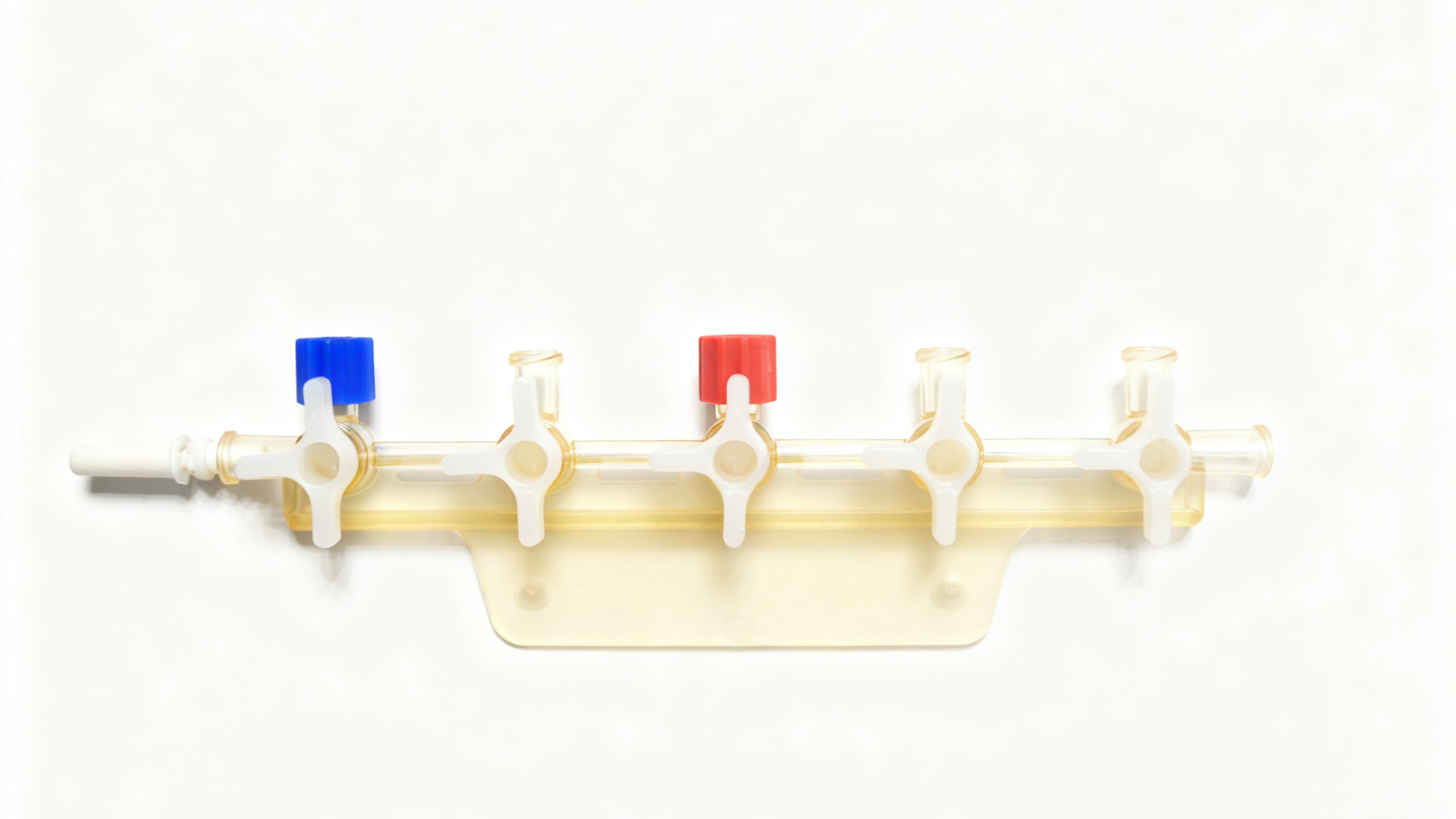

The Multi-Port Manifold

For complex procedures requiring multiple drug infusions or monitor lines, a single stopcock is not enough. This is where a 5-Gang Stopcock Manifold comes in.

- How it works: A manifold is essentially several stopcocks (like three or five) built together into one compact unit on a common rail. Each stopcock (“gang”) can be controlled independently.

- Common use: In an intensive care unit (ICU) or operating room, a 5 gang stopcock manifold might be connected to a central venous line. Each port can be dedicated to a different medication (like sedatives, pain killers, or blood pressure drugs) or a monitoring line. This setup minimizes connections at the patient’s bedside, reducing clutter and potential infection points.

The Critical Role of Precision Injection Molding

A stopcock might look simple, but manufacturing it to medical standards is a significant engineering challenge. Its performance relies entirely on the precision of its molded components.

- Dimensional Perfection: The core and the body must be molded with extremely tight tolerances. The fit between them must be perfect—too loose, and it will leak; too tight, and it will not turn smoothly or could crack. The luer lock threads on every port must also be perfect for secure, leak free connections.

- Material Performance: Stopcocks are molded from rigid, medical grade plastics like polycarbonate. The material must be biocompatible, chemically resistant to drugs, and capable of withstanding repeated sterilization (like with gamma radiation) without degrading or becoming brittle.

- Surface Finish & Cleanliness: The internal channels and the mating surfaces must be perfectly smooth, free of flash (excess plastic) or burrs. Any roughness can trap fluids, host bacteria, or create particles that could enter the fluid stream.

- Ergonomics and Clarity: The handle must be easy to grip and turn, even with gloved hands. Its positions should be clearly marked. The body is often made from clear plastic so air bubbles in the line are visible.

This level of quality cannot be achieved with ordinary plastic molding. It requires a dedicated medical injection molding process with expert mold design, rigorous process validation, and a full quality management system like ISO 13485.

Conclusion

From a simple 2-way stopcock on a hydration line to a complex 5 gang stopcock manifold in critical care, these devices are fundamental to modern medicine. They provide clinicians with direct, tactile control over life saving fluids in a safe and sterile way.

For medical device companies, choosing the right manufacturing partner for these components is crucial. The stopcock is a point of failure that cannot be tolerated. It demands a molder who understands the critical interplay of precision, material science, and regulatory compliance.

Are you developing a device that requires reliable fluid control components? Our expertise lies in molding high-precision, mission-critical parts like stopcocks, where safety and performance are engineered into every detail. Contact us to discuss how we can bring reliability to your fluid path design.