A medical stopcock is a flow-direction control component used within intravenous IV systems.

It determines whether fluid can pass, which pathway is open, or whether all ports are closed.

Within an IV circuit, a stopcock does not regulate flow rate.

Its role is to manage access and direction at points where multiple fluid paths or operations intersect.

The Role of a Medical Stopcock in an IV System

In an IV system, fluid delivery is designed around a continuous and controlled pathway.

Stopcocks are introduced at locations where that pathway must be selectively interrupted, redirected, or accessed.

Common decision points include

- Switching between primary and secondary infusions

- Providing access for IV push or flushing

- Managing multiple medications within a single line

At these points, the stopcock acts as a control interface.

It allows system flexibility without requiring tubing disconnection or reconfiguration.

How a Medical Stopcock Controls Flow Direction

Internal Flow Paths and Valve Positions

Inside the stopcock body is a defined internal flow channel paired with a rotating valve core.

The external handle position determines which ports are connected internally and which remain closed.

Depending on design and orientation, the valve can

- Connect two ports while isolating the third

- Open a single flow path

- Fully block all ports

The valve geometry determines flow continuity.

It does not compensate for pressure, flow rate, or dosing accuracy.

How Stopcocks Interact With IV Flow Control Devices

IV flow rate is established by gravity systems, roller clamps, or infusion pumps.

Stopcocks function downstream or upstream of these devices to define permitted flow paths.

From a system perspective

- Pumps control how much fluid moves

- Stopcocks control where that fluid is allowed to go

This separation of responsibilities is critical.

Using a stopcock to compensate for inadequate flow control introduces instability and operational risk.

Common Medical Stopcock Configurations

One-Way and Three-Way Stopcocks

One-way stopcocks support basic open or closed control in a single flow path.

They are typically used where no redirection is required.

Three-way stopcocks allow fluid to be directed between two independent lines.

This configuration supports secondary infusions, sampling, and flushing without altering the primary circuit.

Stopcocks With Integrated Extension Lines

Some stopcocks are produced with integrated extension tubing.

This reduces mechanical stress at connection points and increases positioning flexibility.

However, extension lines also add internal volume.

In systems where dead space accumulation matters, this trade-off must be evaluated during system design.

Standard and High-Pressure Stopcocks

Standard stopcocks are designed for gravity or pump-assisted IV delivery.

They operate within defined pressure limits and typical infusion conditions.

High-pressure stopcocks are required for applications such as contrast media injection.

These designs demand higher material strength, tighter dimensional control, and more consistent internal sealing.

Benefits and Trade-Offs of Medical Stopcocks

Functional Benefits in IV System Design

When correctly specified, stopcocks enable

- Multiple infusion paths within a single IV line

- Reduced frequency of tubing disconnection

- Controlled access for medication delivery and flushing

They improve operational flexibility while maintaining a closed system.

Practical Limitations and Risks

Stopcocks also introduce system-level constraints

- Internal dead space that must be primed and managed

- Risk of air entry if ports are improperly handled

- Dependence on correct valve positioning during use

These risks are not theoretical.

They must be addressed through both design choices and manufacturing consistency.

Where Medical Stopcocks Are Commonly Used

Stopcocks are commonly applied where IV systems require controlled access without reconfiguration, including

- Secondary IV or piggyback administration

- IV push medication delivery

- Multi-drug infusion pathways

- Sampling or flushing access points

In each case, the stopcock simplifies system operation by reducing the need for repeated disconnection and reconnection.

Manufacturing and Material Factors That Affect Performance

Material Selection for Medical Stopcocks

Medical stopcocks are typically produced from medical-grade thermoplastics.

Material selection affects chemical compatibility, transparency, and long-term dimensional stability.

The material must tolerate repeated valve rotation without deformation.

It must also remain stable when exposed to commonly used IV solutions and medications.

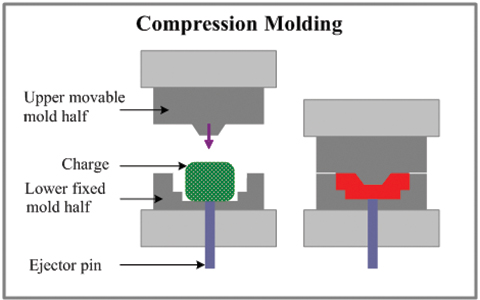

Injection Molding Precision and Internal Sealing

Internal flow channels, valve cores, and sealing interfaces require tight dimensional control.

Minor molding deviations can lead to leakage, increased rotational resistance, or incomplete port isolation.

In IV systems that rely on repeated access and redirection, these effects accumulate.

Consistent injection molding and controlled tooling design are therefore critical to predictable stopcock performance.

At SeaSkyMedical, medical injection molding processes are structured to address these requirements at the component level rather than compensating for them at the system level.

When Standard Stopcocks Are Not Enough

Standard stopcocks are designed for common IV configurations.

They may not meet requirements when systems involve

- Non-standard port orientation

- Integrated tubing or connector geometry

- Application-specific flow path constraints

In these cases, custom medical injection molding allows stopcock designs to align with system architecture rather than forcing design compromises elsewhere.

SeaSkyMedical supports this approach by working with device manufacturers during early design and manufacturability assessment stages.

FAQ

What is a medical stopcock?

A medical stopcock is a small valve used in IV systems to control fluid direction and access. It allows clinicians to open, close, or redirect flow between connected lines without disconnecting tubing. Stopcocks do not regulate flow rate. They manage which fluid pathways are available within the IV circuit.

What is the main function of a medical stopcock in IV therapy?

The primary function of a medical stopcock is flow path management. It enables controlled switching between infusion lines, supports secondary IV delivery, and provides access points for flushing or sampling. Stopcocks help reduce repeated line disconnections while maintaining a closed fluid system.

What does a medical stopcock typically consist of?

A medical stopcock typically consists of a molded valve body, internal flow channels, and a rotating valve core connected to an external handle. The handle position determines which ports are open or closed. Most designs include standardized connectors for compatibility with IV tubing and devices.

Is it safe if air enters the IV line near a stopcock?

Air entry into an IV line is generally undesirable and should be avoided. While very small air bubbles may not cause harm, stopcocks and connectors must be properly primed to prevent air introduction. Correct handling and secure valve positioning are essential for maintaining a closed fluid path.

Contact SeaSkyMedical for Technical Support

SeaSkyMedical provides medical injection molding solutions for IV system components, including flow-control and access interfaces.

Contact SeaSkyMedical for more information or to discuss stopcock manufacturing and customization requirements.