Custom Injection Molded Tube Box Manufacturing

Injection molding is ideal for bulk manufacturing. Our professional, custom-designed sample storage solutions are affordable for laboratories of all sizes.

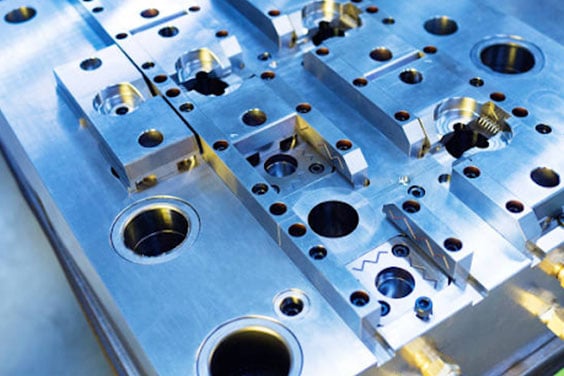

Parts & Mold Design

We start with custom mold and design based on your requirements.

Prototyping

We use 3D printing & prototype to create prototypes for your evaluation and approval before full production.

Plastic Injection Molding

We use precision plastic injection molding to manufacture your specimen products. This process ensures consistency, high quality, and is cost-effective for bulk orders.

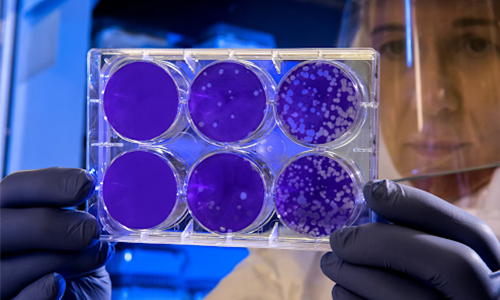

Quality Assurance

All specimen boxes are manufactured under a strict quality management system. We perform necessary validations to ensure product performance and reliability for laboratory use. This is also a consideration for a lab consumables manufacturer.