Your Precise Plastic Molding Company

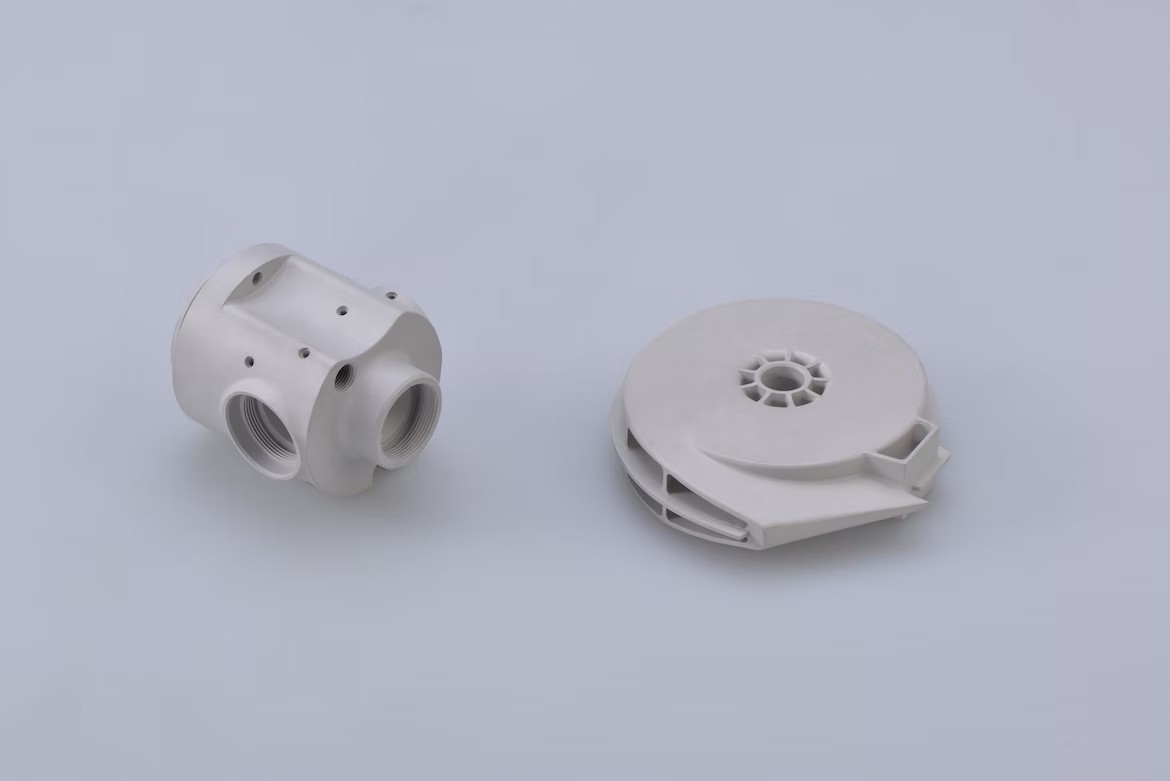

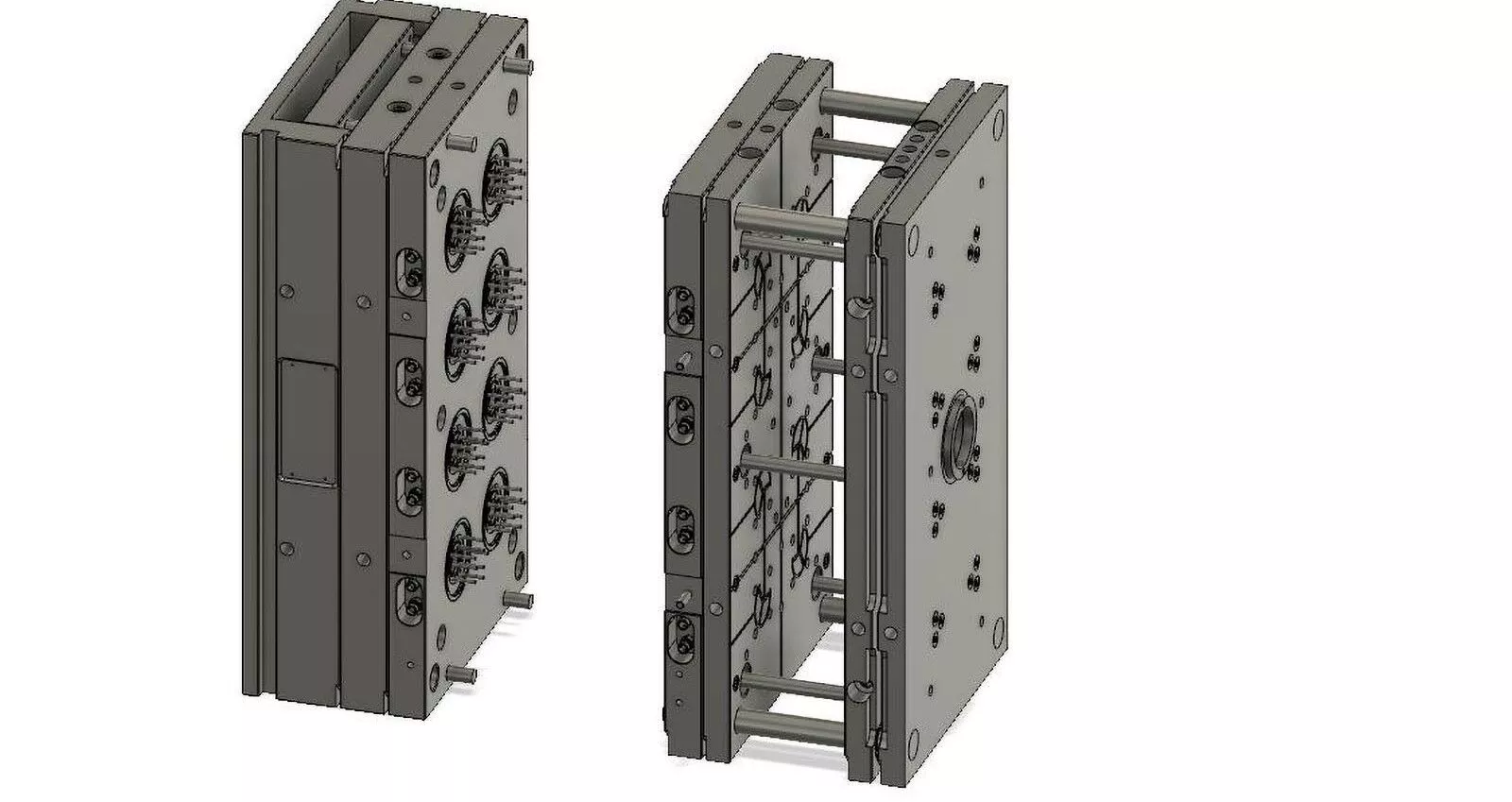

SeaskyMedical is a top-notch ISO-certified plastic injection molding company based in China that produces plastic injection molding solutions for the medical field. From plastic mold design and development to mold building, choosing materials, and delivering manufactured products, we assist you in every stage of plastic molding production.

Being a reliable plastic molding manufacturer, we use the best quality raw materials and manufacture, assemble, and pack the products in the ISO 8 cleanroom with the help of credible injection molding machines. Then, our experts will strictly examine the medical device injection molding products for quality checks to make sure that they match the criteria.