Micro injection molding has become a leap forward, especially with medical devices, where smaller and smarter tools have become the new standard. This manufacturing procedure helps in the production of delicate components with micro-level precision, enhancing inventions in drug-delivery, diagnostics, and less invasive procedures.

Whether it is a syringe tip, endoscope components with micro channels, or micro-needle arrays, micro molding provides exceptional detail and reliability. Keep reading to unravel the scope of medical micro injection molding and why the healthcare industry adopts this technique.

Understanding What is Micro Molding

Micro molding is an advanced production method for manufacturing very intricate and precise components that may weigh less than 1 gram or fa ew millimeters with 10 -100 µm tolerances. It is used in various thermoplastics, metals (micro metal injection design), silicone, and tailor-made micro injection or ultra-fine tools.

Contrary to standard molding techniques, micro injection molding produces micron-level precision measurement that can be replicated over large volumes of production. In the medical field, the medical micro-molding innovation allows the production of polyurethane pacemaker tips, insert-molded battery connectors, micro-needle arrays, and more.

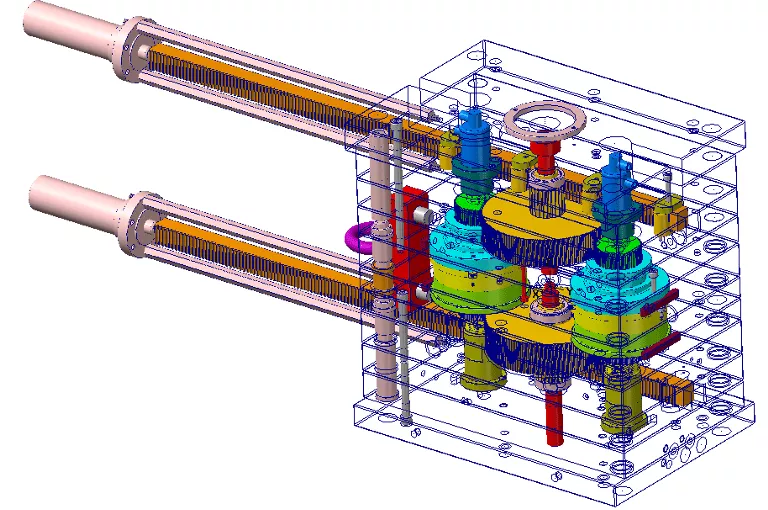

Micro Injection Molding Process

The micro molding process is similar to that of regular plastic molding, although it is used for very tiny components. The process starts with a metal mold designed to suit extremely tiny shapes. The molds can be used to produce parts with very little weight (around 0.1-1gram), with tiny details as small as human hair.

To produce the parts, silicone or melted plastic is injected into the mold. The mold must be properly designed, and the machines must be efficient and accurate to allow molten plastic to run smoothly into the mold to avoid errors with the end product. Cooling time is also important. It must be done quickly and evenly so the design is well-shaped. The micro injection molding process should be done in a dust-free environment because many of these parts are used in medical devices, where hygiene is critical.

Source: iStock

Materials Used in Micro Molding

Micro injection molding uses unique materials that can be used for producing tiny and precise shapes. Typical plastics used are:

- Polyoxymethylene (POM): Strong and smooth – can be used to make clamps and gears.

- Polyether Ether Ketone (PEEK): Commonly used in medical implants because of its strength.

- Nylon, Acrylonitrile Butadiene Styrene (ABS), Polytetrafluoroethylene (PTFE): Ideal for malleable and chemical-resistant components.

- Liquid Crystal Polymer (LCP): Suitable for thin and heat-resistant parts.

In addition, photoresist liquids like SU-8 can be used to build micro-channels suitable for medical test devices.

In selecting materials for micro molding, consider viscosity, thermal properties, and their suitability for medical devices. In medical micro molding, polymers like PEEK, fluoropolymers, or bioresorbable plastics are suitable because of their ability to resist chemicals, and adhere to regulations.

Applications of Micro Molding in Medical

In medical devices, micro molding is a crucial enabler in advancing technology. These applications include:

- Vitrification carrier rods: Used to store and freeze eggs or embryos in fertility clinics.

- Tiny syringe parts, Such as the tips and plungers to help give the right amount of medicine without leaks.

- Endoscope parts: Like micro lenses, flexible tubes, and connectors used in medical imaging.

- Implantable parts: Found in small battery connectors in cardiac devices, micro-needles for painless drug delivery.

Micro metal injection molding aids the development of less invasive tools, diagnostic kits, and implantable life-support systems while ensuring safe, reliable, and small devices.

Source:iStock

Plastic Injection Molding in Medical

In the production of accurate medical parts, microplastic injection molding is a widely used technique. It is a process used in making large quantities of clean, consistent parts in medical practices because it meets medical-grade standards, like hygiene, safety, and quality performance. Some of these medical materials and devices include:

- Test kit parts: For example, pipette, petri dishes, and other small equipment used in carrying samples.

- Syringes and Plungers

- Surgical tools: Like forceps handles and parts of dental devices.

- Prosthetic components: Such as catheters, battery components, optical devices, etc.

Micro plastic injection molding enhances the conventional medical molding by producing only smaller, more complex, and accurate medical parts that the medical injection molding may not be able to achieve. The micro injection molding design exhibits the following features:

- Tiny part size: Tiny geometries, sizes, and tolerances unattainable with standard or traditional molds

- Highly meticulous operations: Its precision engineering ensures tight seals, smooth flow, and tolerance level critical for the reliability of small medical components.

- Cost and efficiency: The smaller molds are way cheaper and easier to manufacture, but with the use of special machines.

- Durability: Small molds cool and solidify fast, which makes them perform better.

All of these advantages have helped in innovative medical tools, from lab diagnostic kits to biomedical implant devices.

Material Selection for Medical Micro Molding

Choosing materials for medical micro molding goes beyond selecting a biocompatible polymer; it is a tactical decision that affects dimensional accuracy, mold flow, compatibility with sterilization methods, and product efficacy. Micro molded elements are always very small with extremely fine details and a miniature tolerance level; hence, any slight inconsistency in material or selection decisions can undermine product function and quality.

The common materials used are PEEK, LCP, Polycarbonate (PC), and Thermoplastic elastomers (TPES). Characteristics of these materials include: strength, flexibility, dimensional accuracy, stable flow characteristics, and the ability to withstand various sterilization methods such as gamma radiation or autoclaving. Some resins are perfect for prolonged implantation, while some are designed specifically to reduce leachables or extractables, which is important for the safety of patients.

Aside from selecting a material, mold design and tooling also affect the way a material performs in the production phase, and with the final product. Theoretically, a high-viscosity polymer might offer optimal performance, but if the mold’s gates, runners, or cooling channels are not customized for that material, underfilling or overflow can occur. The mold surface can influence how the materials fill ultra-fine features like optical tips or microfluidic channels.

In addition, mold materials must be compatible with the formulated resin. For instance, hard stainless steel or nickel must be capable of handling abrasive materials and thermal cycling chemicals. Another crucial component is the cooling system embedded in the mold- it influences how quickly and smoothly the part hardens, which in turn determines shrinkage or deformation of the components and internal stresses.

Maternal selection and mold design are interconnected aspects. Both considerations are crucial and must be finely tuned to ensure consistent and efficient results, especially in the production of sophisticated devices like implantable components, surgical aids, and diagnostic cartridges.

Mold Design for Micro Medical Injection Molding

In medical micro injection molding, mold design does more than producing a definite shape- it determines the function, durability, and dimension of the finished injection-molded product, where the designs are measured in millimeter range or less and extremely tight tolerances, leaving little room for error. What differentiates conventional and micro medical injection molding?

Traditional medical injection molding is used for components like inhaler housings, surgical instrument handles, and IV connectors. These molds prioritize efficiency and repeatability, operating within tight tolerances of ±50 to ±100 microns.

Micro medical injection molding, on the other hand, performs its function on a very small scale. For example, micro needles, drug-delivery systems, prosthesis, or implantable devices weigh less than 1 gram and with tolerance levels of ±5 microns, making micro medical injection molding the best fit for their production.

Ultimately, micro molding is crafted with extreme precision. Tool cavities, parting lines, and cores must align with micron-level accuracy. The finishes require <1µm roughness to mitigate contamination, aid fluid flow, and be fit for optics and other medical devices.

Gate design is another crucial part of the mold. Traditional molds have wider gates where fan or tab styles are common. However, micro molders use smaller gates, like tiny edge or pinpoint gates. This allows plastic to flow smoothly into the mold without pressure, air bubbles, or overflow around the edges.

Micro mold designs don’t only make small parts, they can make very complex medical shapes that regular molds cannot. These features include:

- Micro optics and lenses

- Thin-walled prosthetics

- Microfluid channels suitable for lab-on-a-chip devices.

Quality mold design is a vital component of micro medical molding. A well-designed mold produces consistent dimensions, prevents post-processing errors, and ensures product consistency.

When to Choose Micro Molding Over Conventional Injection Molding for Medical Devices

Source: Istockphotos

In the fast-changing sphere of the production of medical devices, accuracy, miniaturization, and quality performance are important to successful production. As medical accessories become more compact and operationally complex, producers face the problem of producing extremely complex components with rigid tolerances. This is when micro molding becomes a better choice for medical devices as opposed to conventional injection molding. The other factors include;

What makes micro-injection moulding different is its unique feature of maintaining the integrity of complex designs while producing mass production. Also, micro plastic injection molding ensures consistency in quality production. It has tight control over necessary characteristics such as pressure and temperature during the manufacturing process.

Micro molding processes make use of high-strength alloy materials and pass through precision machining to implement mold longevity and the uniformity of molded parts, with the inclusion of overmolding. To ensure strength and even flow of the injected material, medical micro injection molding prioritises the placement of the gate location in the mold. It is important in conventional injection molding. However, it is considered more important in the micro molding process due to the compact size and stringent tolerances needed.

Regulatory Compliance

In the micro molding process, adherence to regulatory standards is key, ensuring the safety of patients. Micro injection molding companies should implement a quality management system in line with ISO 13485:2016 and, where needed, FDA 21CFR 820. This structure oversees document control, traceability, source quality, change control, and preventive/corrective measures. Also, incorporate comprehensive risk management based on ISO 14971:2019 to examine, identify, and eliminate risks all through the lifespan of the product. This is done through the observation of material selection, design, and manufacturing process.

Material selection should be controlled by only adopting materials certified as biocompatible with ISO 10993-1 and/or USP Class VI. To avoid contamination, materials should be stored under defined humidity conditions or temperature. Suppliers of these materials must be inspected and picked by their compliance with ISO 13485 and biocompatibility rules such as ISO 10993. Suppliers of tools and resins must properly document necessary information, with the inclusion of change notification systems and certificates of analysis.

Maintain clean rooms with certification ISO 14644-1 for micro metal injection molding. Ensure constant particulate and microbial surveillance, HEPA filtration, and own measures to keep a sterile-friendly manufacturing industry. In addition, establish critical process parameters checked by IQ/OQ/PQ standards, such as melt temperature, mould temperature, and cooling time, to monitor consistency.

Challenges and Innovation in Micro Medical Injection Molding

While micro insert molding helps to produce precise, extremely small medical parts, it is also associated with some challenges. These key challenges include;

- Device Precision and Durability

To manufacture moulds with small-scale attributes, there is a need for high precision in tools, usually in the scope of sub-micron tolerances. Conventional mold-injection machines may not produce the needed accuracy, and features are susceptible to damage. Micro injection molding companies should employ advanced CNN, EDM, or laser precision machining with high-resistance steel or ceramics.

- Material Keeping

Materials used for micro injection molding should be without contamination or degradation. Micro components usually require extremely engineered resins (PEEK or LCP ) that are vulnerable to heat or moisture. Medical micro injection molding companies should use well-controlled material feeding mechanisms, usually with specific micro injection units.

- Components Ejection and Management

Due to the delicate nature of the micro parts, conventional ejection makes removing or ejection uncertain. The small size of parts makes the removal and handling unreliable. Consider the implementation of vacuum-vacuum-assisted ejection or customized robotic mechanisms with visual guidance.

- Process Management

To ensure surface quality and uniformity, there is a need for consistency and repetition in processes. Any change, whether minor or major, in pressure, temperature or the flow of material can alter the final part. Therefore, high-end system examination and closed-loop controls should be adopted.

Conclusion

Medical micro injection molding is transforming the creation of miniature and precise medical parts. Unlike conventional micro molding, it is a perfect choice for manufacturing complex, high-tolerance components on a small scale. Successful production in medical micro injection molding is based on the selection of biocompatible materials, managing mold design, and implementing regulatory adherence such as ISO13485. Though challenges like maintaining precision and constant quality are seen, advancements in tools, processes, and materials are upgrading the medical space. As medical devices are becoming more specialized, medical micro molding is important for future health solutions.