When designing and injection molding any curved medical part, such as a syringe with a curved tip or a curved tip dental syringe, designers utilize their engineering and material knowledge. Most of the time, these medical devices are utilized in delicate medical procedures, as they need to be structurally sound while maintaining ergonomic efficiency and allowing for possible one-handed operation. The design challenge with all medical design parts that are bent or curved, whether it is a curved tip irrigation syringe or curved plastic connecting fittings, is how to engineer a shape that can be manufactured without losing practicality. We will use medical curved-tip syringe models to show how these approaches and processes are accomplished.

Typical Bent-Design Medical Injection-Molded Parts

We typically think of the bent-design approach with medical injection molded parts, whether it is a curved tip on a medical syringe, the curved tip of a dental syringe, or perhaps curved silicone tubing on an endoscope. Here are four popular representations of a medical product in the curved shaped family; include the intended usage and function for each identifying part:

1. Curved Tip Syringe

The curved tip syringe, often referred to as a curved tip dental syringe or curved tip irrigation syringe, is commonly found in dental practices, wound care facilities, and for surgical irrigation purposes. The curved syringe allows the clinician to flush, appropriately, limited spaces with minimal discomfort to the patient. These syringes are typically made of a polymer that is safe with maximum decorative flavor plaque and sufficiently strong to withstand fluid pressure. The nozzle’s smooth curve reduces splash back, can direct fluid straight ahead, and can allow for single-handed maneuvering.

Source: iStock

2. Pipette Droppers Elbow

The pipette dropper’s elbow is a small, narrow, and curved plastic piece that is typically Φ3.2 mm in diameter and 27 mm long. It also has ribs on the inner surfaces that seal against the rotary valve. This type of bent tubing is commonly found as the falling mechanism on most laboratory and ophthalmic droppers to help dispense controlled amounts of liquid. Maintaining typical roundness and very little eccentricity (≤.05 mm) is particularly important, ensuring consistent flow rates and airtight sealing. Any small amount of eccentricity during the injection molding process can create liquid leakages or non-functioning products from manufactured parts, so a high level of precision is necessary for the dimensions.

Source: iStock

3. Bending Section of Endoscope

The bending section of the endoscope is made up of thin-walled curved plastics that are typically in multi-segmented joints with a wall thickness of 0.3 to 0.5mm. The bending section plays an important role in helping the flexible endoscope travel through the complex anatomy of the internal organs while still being considered minimally invasive. The bending section will need to provide high rigidity and very good torsional rigidity. The articulation challenges and small size of the bending section bring concerns for injection molding this part in downstream issues such as tooling, optimized flow path, and accurately controlling the cooling against warpage and stresses.

Source: iStock

4. Medical Catheter Connectors, such as Intravenous (IV) Connectors

The connectors are usually formed from a curved plastic component shaped like an L or U. Medical catheter connectors enable intravenous therapy by connecting tubing to either a cannula or fluid bags. The inner surfaces must remain smooth to not disrupt the flow, and the external junction points must be sealed so they are airtight and maintained with zero flash (excess material). The molding of the connector must have a very high dimensional control tolerance, especially at the points where tubing comes together at angles, as any deviation from the tolerance or flashing will lead to leakage or contamination that could endanger the patient. This makes the alignment of the molds very important, especially with multiple molds with several gate placement positions in a manufacturing setup.

Source: iStock

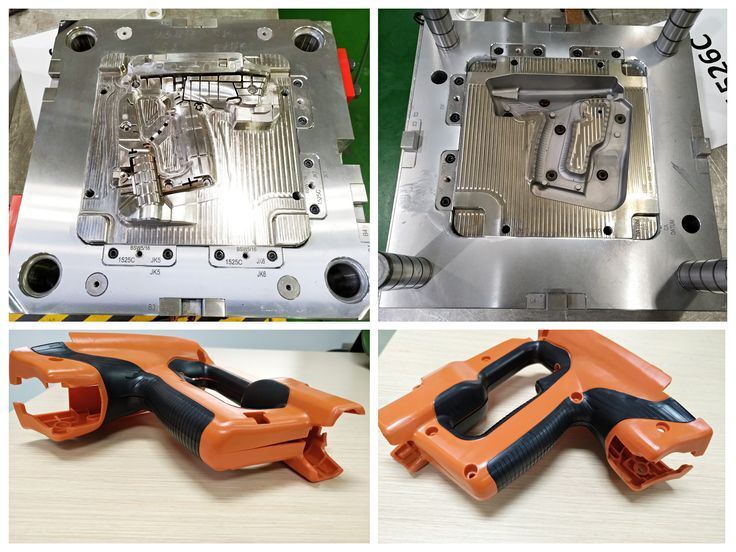

Mold Design and Manufacturing Challenges

Mold design control is important when producing bent components like the curved tip syringe, curved tip dental syringe, or elbow-shaped pipette droppers. These pieces tend to involve very thin walls and fine, bent geometries that can lead to many molding problems.

- Dimensional Accuracy Issues

Eccentricity and Roundness Deviation: The process of creating bent components can lead to the shifting of the core pin, causing wall off-centering. Even a maximum roundness deviation of 0.05 mm for a dripper head is exceptionally important, as it indicates very minor leaks or flow.

Uneven Shrinkage: The differing wall thicknesses in curved sections cause the cooling rates to differ, resulting in shrinkage issues that can cause warpage as much as 0.15 mm. For example, the original deformation of a needle blood return cap portion was approximately 0.058 mm after it was molded.

- Structural Molding Defects

Incomplete Filling: Curvature in channels less than 0.3 mm in a curved plastic syringe increases flow resistance, which in turn will produce short shots (incomplete fill) resulting in loss of function.

Demolding Damage: Curved areas can create unnatural holding forces resisting motion when demolding. The resultant drag can lead to scratches or distortion, or even occur as a sticky slider issue in dripper components.

- Residual Stress and Deformation

Internal Stress Concentration: Cooling curves are nearly always non-uniform, leaving behind zones of stress ‘burdened’ with heat. The internal residual stress could lead to cracks, bends, or deformation in the initial product.

Weak Weld Line Strength: In molds with multiple gates, weld lines will frequently occur at curved sites. The weld lines have points of reduced performance of up to 50% reduction of mechanical strength.

Common Defects and Causes in Injection-Molded Curved Designs

Some common defects often encountered and their causes are:

- Eccentricity and roundness deviation → Movement of the core pin

- Warping and deformation → Different cooling and shrinkage

- Short shots → High flow resistance in thin curved channels

- Scratches or drag marks → Poor demolding force distribution

- Weak weld line → Flow crossing from multiple gates at bends

Defects can be avoided by understanding them. This will ultimately enhance the design and service life of the curved tip syringe and other curved plastic components used in medical device applications.

Core Challenges and Solutions

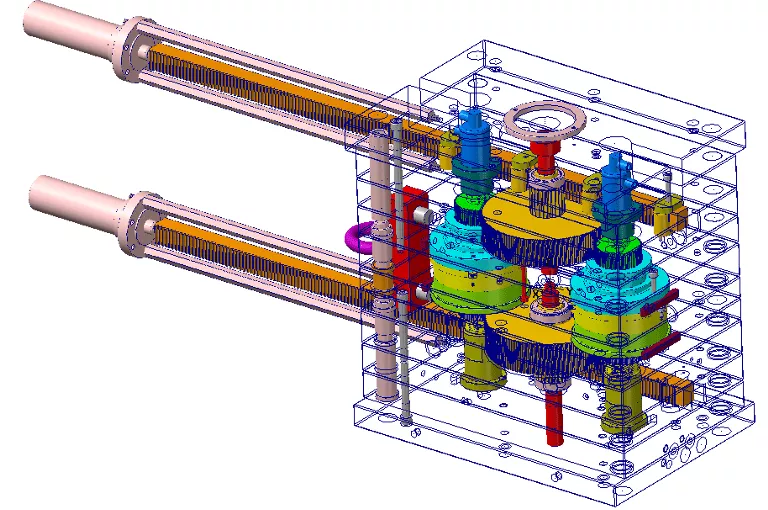

- High-Rigidity Mold Structure Design

The design of injection technology is based on the nano-structure feature of the toggle lever mechanism ratio, speed ratio, and force amplification ratio. It poses a challenge due to the interaction between design malleability, dimensional accuracy, and mechanical strength. To avoid challenges, use hardened tool steel (e.g., H13, S7, or P20) instead of aluminum or soft steel. Apply advanced machining methods like EDM, CNC milling, and polishing with micron-level accuracy. Use a fixed-section ratio of at least 1:1 (e.g., dripper core fixed section ≥27mm), with pre-hardened 8407 steel (HRC48). Use tapered positioning sleeves to improve offset load resistance.

- Flow and Deformation Co-Optimization

This is a major challenge when crafting injection molding curved medical devices. Designers must strategically stabilise fluid dynamics and structural mechanics with the use of material science, simulation, and mold design. Below are ways to tackle this challenge;

- The Box Behnken Design

The Box Behnken Design is used to find the best parameters. The five major molding parameters are melt temperature, mold temperature, injection pressure, holding pressure, and cooling time. Balance the melt temperature between great flow and measured shrinkage with 65°C. Also, get your desired result with a melt temperature of 230°C and a holding pressure of 40%.

- Intelligent Process Parameter Control

Intelligent Process Parameter Control allows fact-driven optimization of the molding process, reduces defects, increases accuracy, and enables the structural quality of curved medical parts.

- Innovative Gating System

Innovative Gating System is introduced to fine-tune and melt the flow path, enhance pressure balance, and minimize stress accumulation during solidification.

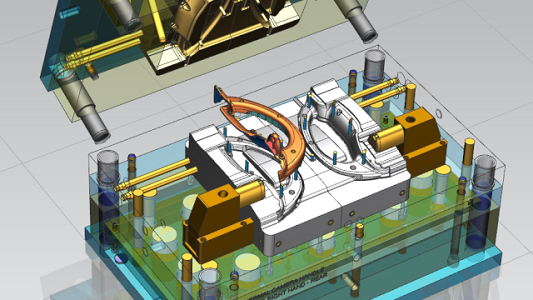

- CAE-Driven Anti-Deformation Compensation Factor

In creating medical accessories, precision is very important, which is why injection molding is a critical issue. Designers use the CAE (Computer-Aided Engineering) technologies to solve these issues. However, this method still poses some challenges. It includes performing the mold through the use of CAE simulations (Moldex3D) to eliminate expected deformations, using a reversed compensation factor (e. G., s=1.1) to minimise malformations to the barest minimum.

Also, response surface optimization employs equations from methods like BBD to connect parameters, ensuring automatic optimization.

- Innovations in Demolding and Cooling Systems

One of the major ingredients of the injection molding of curved plastic is the cooling system. In order to ensure the ultimate quality of the curved medical device predicted, the cooling and demolding system needs to be established. These systems include;

- Stepped Ejection Mechanism

It makes use of ejector pins of different sizes. Employ the extended sleeve-type rods. Stepped pins are usually used to eject through or blind holes.

- Conformal Cooling Channels

Conformal Cooling Channels make use of three-dimensional methods tailored to curved devices, enhancing cooling effectiveness by 40% and minimising warping

- Microcellular Foaming

Cooling trends also include MuCell Microcellular Foaming. It inputs ultra-critical liquid to reduce melt viscosity and shrinkage, increasing deformation by 30% for thin-walled components.

- Hot-runner Technology

Also, hot-runner technology with the inclusion of multi-gate side injection depletes warpage in accessories like blood tubes from 1.5mm to 0.15mm.

- Smart Mold 3D Printing

Smart Mold Three-dimensional printing allows flexible molds for quick prototyping.

Conclusion

Designing injection-molded medical devices is not just shaping plastics, it’s a process that deals with precision, safety, and functionality. As the production of these designs brings forth challenges, they are also met with solutions to curb the challenges. At the end of it all, the success of the designs depends on the combination of material design, mold paths, and intelligent processing to achieve outstanding results. Reach out to get access to quality devices tailored to your needs.