Turnkey manufacturing for medical devices is a single-provider manufacturing model in which one partner assumes responsibility for the full production chain.

This responsibility typically extends from early design alignment through manufacturing, assembly, packaging, and delivery of a market-ready medical device under a controlled medical device contract manufacturing framework.

Unlike conventional contract manufacturing, turnkey manufacturing consolidates technical decision-making, process ownership, and quality accountability under one integrated system.

Scope of Turnkey Manufacturing in Medical Devices

In medical device production, turnkey manufacturing is defined by scope integration, not by a single process.

The model is commonly applied when multiple regulated steps must remain technically aligned over time.

A typical turnkey scope includes:

- Product design and manufacturability alignment

- Medical-grade material selection and sourcing

- Tooling and mold development

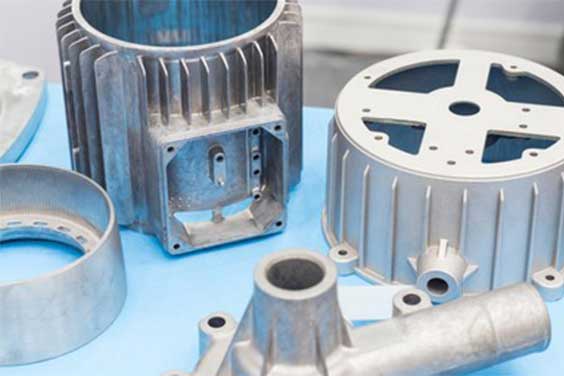

- Component manufacturing

- Assembly and secondary processing

- Packaging coordination and shipment preparation

The defining factor is that process interfaces are managed internally, rather than transferred between vendors.

How Turnkey Manufacturing Is Applied in Medical Device Production

Design Review and Manufacturability Decisions

Turnkey projects usually begin with design review focused on manufacturing behavior.

At this stage, design for manufacturability is applied to reduce downstream tooling and process risk through structured product development activities.

Common activities include:

- Geometry refinement based on molding flow and shrinkage

- Tolerance allocation tied to achievable process capability

- Early screening of medical-grade material selection options

Once tooling is released, many of these decisions become difficult to reverse..

Tooling Design and Process Control Setup

Tooling is developed alongside process definition, not as a standalone task.

Gate location, cavity balance, and cooling layout are defined to support stable cycle-to-cycle output.

For injection molded medical components, tooling design often sets the practical limits for:

- Dimensional repeatability

- Cosmetic consistency

- Long-term process capability

In turnkey models, tooling ownership and process documentation are typically managed together to avoid interface gaps.

Manufacturing and Assembly Under Controlled Conditions

After tooling validation, production moves into controlled manufacturing.

Processes are operated within documented windows rather than fixed machine settings.

Common turnkey manufacturing activities include:

- Medical plastic injection molding

- Insert molding and overmolding

- Cleanroom medical device assembly

- Secondary operations such as trimming, bonding, or inspection

Assembly sequencing is usually defined to minimize handling and reduce contamination riskination risk.

Quality Control and Compliance Throughout Production

In turnkey manufacturing, quality control is embedded throughout the process.

Inspection points are defined based on process risk rather than convenience.

Typical controls include:

- In-process dimensional verification

- Lot-level traceability

- Documented process validation

- Final inspection prior to packaging

This structure allows process deviations to be identified before nonconforming product accumulates.

Packaging and Delivery as Part of Manufacturing Output

Turnkey manufacturing commonly extends through packaging and shipment preparation.

This ensures that components leave production in a usable and controlled state.

Packaging activities may include:

- Clean or controlled packaging

- Multi-part kitting

- Labeling coordination based on customer requirements

Logistics is treated as part of the manufacturing outcome, not a separate function.

Typical Turnkey Manufacturing Structures

Full Lifecycle Turnkey Manufacturing

One provider manages all stages from early definition to delivery.

This model is suitable when internal manufacturing resources are limited.

Manufacturing-Focused Turnkey Services

Design ownership remains with the customer while manufacturing and assembly are integrated.

This approach is often used for established devices entering higher production volumes.

Process-Specific Turnkey Integration

Only selected stages are consolidated under one provider.

Examples include tooling plus molding, or molding plus cleanroom assembly.

Practical Advantages of Turnkey Manufacturing

Turnkey manufacturing reduces complexity by limiting process handoffs.

Common advantages include:

- Fewer supplier interfaces to manage

- More predictable manufacturing timelines

- Centralized accountability for quality outcomes

- Reduced risk of documentation inconsistency

These benefits become more pronounced as regulatory and process complexity increases.

Limitations and Engineering Trade-Offs

Turnkey manufacturing also introduces constraints that require evaluation.

Typical considerations include:

- Increased dependency on a single manufacturing partner

- Reduced direct control over individual process steps

- Initial effort required to align documentation and responsibilities

Projects with frequent design iteration or rapidly changing suppliers may not be well suited for full turnkey models.

Medical Device Applications Suitable for Turnkey Manufacturing

Turnkey manufacturing is commonly applied to:

- Disposable medical components

- Diagnostic and laboratory consumables

- Precision plastic housings

- Multi-part assemblies requiring cleanroom handling

It is most effective when repeatability and long-term stability are prioritized.

Role of Injection Molding in Turnkey Medical Manufacturing

Plastic injection molding is often the central process in turnkey medical production.

It allows consistent geometry, material control, and scalable output.

SeaSkyMedical typically applies turnkey manufacturing principles to projects involving:

- medical injection molding for disposable and reusable devices

- custom medical plastic parts requiring controlled tolerances

- cleanroom medical manufacturing integrated with molding and assembly

By managing tooling, molding, and assembly within one system, process variability can be reduced and documented more effectively.

When Turnkey Manufacturing Makes Sense

Turnkey manufacturing is suitable when:

- Multiple regulated processes must remain aligned

- Long-term production stability is required

- Supply chain interfaces need to be minimized

It is less suitable for early-stage exploratory development or projects requiring frequent supplier changes.

Key Takeaways

Turnkey manufacturing for medical devices is a structured approach to managing complex production under a single responsibility framework.

Its value lies in process integration and controlled decision-making rather than speed alone.

For plastic-based medical devices, integrating injection molding, assembly, and packaging within one controlled system is commonly used to support quality and repeatability.