The process of plastic injection molding is a complex one that involves numerous factors. One of the most critical factors in this process is the injection pressure molding. This article seeks to delve into the intricacies of injection pressure molding, its types, its role in plastic injection molding, potential defects arising from improper injection pressure molding, and how to adjust it for improved part performance and durability.

What is Injection Pressure?

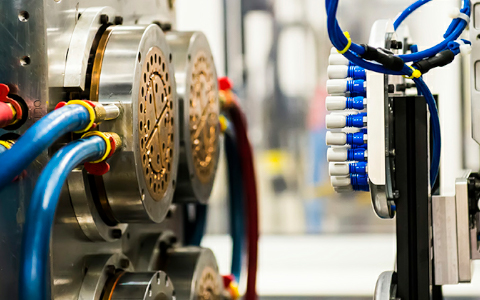

Injection pressure is the force applied by the screw of the injection molding machine to push the molten plastic material into the mold cavity. It is a vital parameter in the process of injection molding and is essential for overcoming the resistance of the molten material from the barrel to the cavity, giving the material a certain filling rate, compacting it, and establishing a direct relationship between the material and the mold.

The injection pressure is regulated by an injection pressure regulator, and it is balanced against the clamping pressure of the machine. It is influenced by various factors such as the type of plastic, the complexity of the plastic part, the wall thickness of the plastic part, the nozzle pressure, the nozzle structure, the mold gate size, and the types of the injection part. The injection pressure typically ranges between 40-200MPa.

Types of Injection Pressure

In the course of injection molding, three types of pressure parameters are often encountered. These are the injection pressure, holding pressure, and backpressure. These pressures directly impact the plasticization of the plastic and the quality of the product, cavity pressure. It is important to note that the distance between the mold and the nozzle, commonly referred to as the “fill height,” is measured in square inch.

Holding Pressure

The holding pressure refers to the pressure that is maintained on the melt after the mold is filled and until the gate freezes or the pressure loss is removed by cycle timer control. In most cases, it’s the holding pressure that determines shrinkage, not the initial injection pressure. The required level of holding pressure for semi-crystalline thermoplastics is crucial to ensure the quality of the final product.

Backpressure

Backpressure, also known as plasticizing pressure, refers to the pressure on the head of the screw when the melt is turned back by the reciprocating screw. The magnitude of this pressure can be adjusted by the relief valve in the hydraulic system, high back pressure.

The Role of Injection Pressure in Plastic Injection Molding

Injection pressure plays an integral role in the plastic injection molding process. Due to the viscous nature of molten thermoplastic polymers, viscosity, an extreme amount of pressure is required to mold these materials into various parts. The melting of plastic is a critical factor in the injection molding process, and understanding the impact of injection pressure on the melting process is crucial for producing high-quality plastic parts.

The injection pressure is necessary to maintain the desired polymer flow rate during the filling stage, ensuring that the mold cavity is adequately filled with the molten material and high pressure. The clamping force rate of the injection mold machine, 50-ton machine, is an important factor to consider when determining the appropriate injection pressure for a given mold and material.

Once the filling stage is complete, the injection molding machine automatically switches to the packing stage, where the machine controls injection pressure rather than flow rate. Controlling the pressure during this stage allows the polymer flow rate to slow down as the cavity becomes full.

What Are the Potential Defects That Can Arise from Improper Injection Pressure?

Improper injection pressure can lead to several defects in the final product. These defects can range from cosmetic issues to structural problems that affect the overall performance and durability of the part. Some of the potential defects that can arise from improper injection pressure include:

Short Shots: This occurs when the mold cavity is not filled completely. The result is a part that is smaller than intended and lacks the necessary features.

Voids: These are empty spaces within the part that can weaken its structural integrity.

Flash: This is excess material that seeps out of the mold cavity and forms a thin layer around the part. Flash can result in a part that doesn’t meet the required specifications and requires additional processing to remove the excess material. It is important to consider the tonnage of an injection molding machine to prevent tons of flash from occurring during the molding process.

Sink Marks: These are depressions in the surface of the part that occur when the outer layer solidifies before the inner material. Sink marks can affect the aesthetic quality of the part and may also weaken its structure, shape of the part. It is important to note that sink marks can be as small as a few thousandths of an inch, but they can also be several inches in diameter, depending on the size and shape of the part.

How to Adjust Injection Pressure to Improve Part Performance and Durability?

Adjusting the injection pressure, higher injection pressure, pack pressure, linear pressure, and the filling phase of the injection molding cycle is crucial for improving the performance and durability of the parts produced in the case of a piston injection molding machine. Here are a few methods to consider:

Multi-Stage Injection: In this method, the injection process is divided into multiple stages, each with a different injection pressure. The first stage controls the gate, the second stage controls the main body, the third stage fills the product to about 95% of its capacity, and then the pressure is maintained to complete the product.

Injection Speed Controls: The injection speed controls the melt filling rate. The injection pressure serves as a guarantee for this filling rate. The injection position controls the melt flow position, while the holding pressure is used to adjust the product weight, size, deformation, and shrinkage.

Proper Injection Pressure Selection: Selecting the right injection pressure based on the mold temperature, storage temperature, material flowability, product thickness, and complexity is crucial. Higher injection pressures are recommended for more complex shapes and longer processes, while lower pressures are recommended for materials with good flowability.

| Method | Description |

| Multi-Stage Injection | This method divides the injection process into multiple stages, each with a different injection pressure. Stage 1 controls the gate, stage 2 controls the main body, stage 3 fills the product to about 95% of its capacity, and then the pressure is maintained to complete the product. |

| Injection Speed Controls | These controls are for the melt filling rate. The injection pressure guarantees this filling rate. The injection position controls the melt flow position, while the holding pressure adjusts the product weight, size, deformation, and shrinkage. |

| Proper Injection Pressure Selection | Choosing the right injection pressure is crucial and should take into account the mold temperature, storage temperature, material flowability, product thickness, and complexity. Higher injection pressures are suggested for more complex shapes and longer processes, while lower pressures are suitable for materials with good flowability. |

Conclusion

Understanding and controlling injection pressure is key to the successful production of high-quality plastic injection molded parts. A combination of high-quality injection molds and experienced injection molding company is required to ensure that the injection pressure is set correctly and that the process results in high-quality products.

Seaskymedical can meet your needs in producing high-quality plastic injection molded components. If you prepare to start a plastic injection molding project, please contact us now!