A medical device like an intravenous (IV) set is not just a simple tube. It is a carefully engineered system where each part has a specific job to ensure safety, control, and reliability. Understanding how these components function together is key to designing better medical devices.

Let’s take a common example—a paediatric giving set—and explore the role of each part. This will show how precision injection molding creates the vital links in the chain of patient care.

1. The Starting Point: The Paediatric Drip Chamber

The fluid journey begins here. This chamber has a special “60-drop/ml micro dripper.” Its job is to let the fluid from the bottle fall in precise, visible drops. A healthcare worker can actually count these drops to set the flow rate manually. It includes a filter and an air vent, ensuring no air bubbles or particles travel down to the tiny patient.

2. The Control Center: The Roller Valve & C-Clamp

- Precision V-track Roller Valve: This is the main control for the fluid’s speed. By rolling the clamp along the special tubing track, the nurse pinches the tube to a specific width, creating a precise opening. This controls how fast or slow the fluid flows, which is critical for accurate dosing.

- The C-Clamp: This is the emergency stop. If the flow needs to be stopped immediately, the nurse can press this clamp to fully pinch the tube shut instantly. It works without disturbing the careful setting of the roller valve.

3. The Pathway: Specially Designed Tubing

The tubing is not all the same. It has three key sections:

- Pump-Specific Tubing: Near the top, this section has exact thickness and flexibility. It is designed to work perfectly with infusion pumps, ensuring the pump can push fluid with very high accuracy.

- Mid-Section Tubing: This part is toughened. Its job is to resist twisting and kinking, which could block the fluid flow (occlusion) even if the line gets slightly tangled.

- Kink-Proof End Section: At the patient end, this tubing is designed to loop very tightly without closing up. This allows for a neat, compact setup at the bedside, reducing trip hazards.

4. The Access Points: Y-Port Injection Sites

Found in the middle and near the end, these are like safe doors into the system. Each has a self-sealing membrane. A nurse can insert a syringe needle here to inject medication directly into the flowing IV line without stopping it or making an unsafe connection. They are marked “NON-latex” for patient safety.

5. The Vital Links: Luer Connectors – Where Modularity Meets Security

This is where the system connects to the world. Luer connectors are the universal standard for leak-proof links.

- Proximal In-line Luer Connection (Female): This port, near the top of the set, is all about modularity. Its purpose is to “allow addition of extensions, flow regulators and Y-connections.” It lets clinicians customize the setup for each patient’s needs by easily snapping on other safe, compatible parts.

- Male Luer Slip Lock (at the patient end): This is the final, most critical connection. It is designed to attach securely to the patient’s catheter. The “slip lock” design is key: it pushes in easily (slip) and then the rotating collar threads on to lock. This dual action prevents any accidental pulls or movements from disconnecting this lifeline.

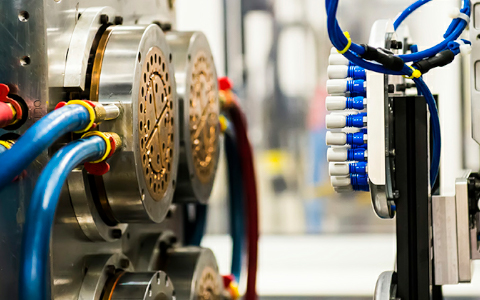

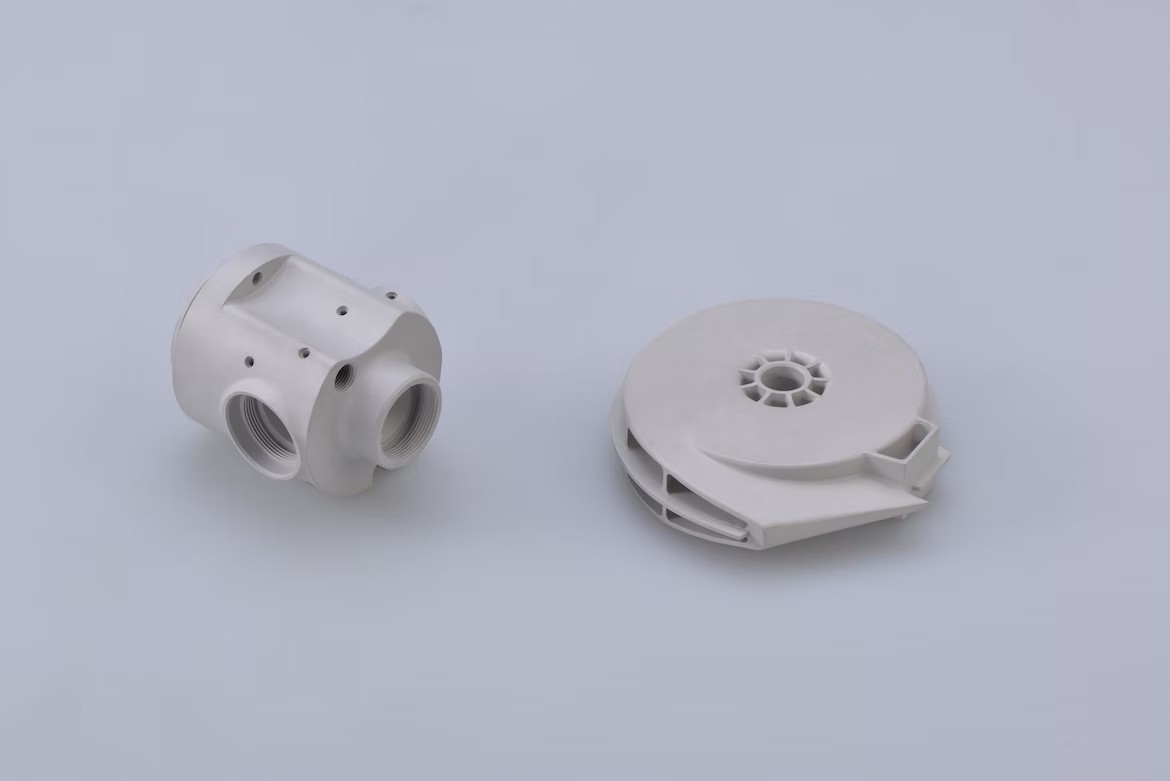

6. Why Precision Injection Molding Makes It Possible

Every part we just described depends on high-quality, consistent manufacturing.

- The drip chamber must be clear and have a precise dropper.

- The roller valve must move smoothly along its track.

- The Y-port membrane must reseal perfectly every time.

- Most critically, the luer connectors must have perfect dimensions. Their famous 6% taper must be exact to create a leak-proof seal. The lock collar must thread effortlessly. Any flaw here risks leaks, disconnections, or contamination.

This is the specialty of medical injection molding. It uses expert mold design, medical-grade plastics, and tightly controlled processes to make millions of identical, safe, and reliable parts.

Conclusion

A safe IV set is a symphony where each component plays its part. The chamber measures, the valve controls, the tubing carries, the ports allow access, and the luer connectors link everything together securely. This deep understanding of system design and component function is what guides true medical device manufacturing.

Do you need a partner who understands how to mold the critical parts that make medical systems work? From precision luer connectors to complex functional components, our expertise is in creating the reliable links in the chain of care. Contact us to discuss your device design.