As a medical device business, you have several options for how to outsource the production of your products. One of which is a medical device contract manufacturer. But how does it differ from the usual parts maker, and what contract manufacturing services do they bring to the table?

Let’s look at what medical device contract manufacturers do in this article, along with the services they can offer. By the end, we also aim to help you see why partnering with one will be an optimal choice to streamline your business.

Product Concept and Development

Assisting businesses in creating injection molded plastic medical devices is the primary task of a contract manufacturer. Unlike the typical parts maker, contract manufacturers are also responsible for conceptualizing and developing bespoke products according to client and market specifications.

Seasky Medical has a team of expert designers who draw upon 11 years of industry expertise in crafting custom injection molded plastic medical devices. We listen closely to your project needs and develop medical devices with detailed features and improved performance. Our designers can also modify existing part designs, aligning them to your project goals with full efficiency.

Design for Manufacturability (DFM)

Design for Manufacturing or DFM is a production concept where products are designed and produced with a focus on streamlining the process without compromising form and function. Seasoned DFM contract manufacturers address potential concerns early in the design process and implement steps for easy and consistent parts fabrication.

As an established contract manufacturer of injection molded plastic medical devices, Seasky Medical leverages its decade-long experience in implementing DFM principles in each project we handle. From the early stages of production, take critical steps to make sure that parts are easy to reproduce and materials are readily available for swift mass production.

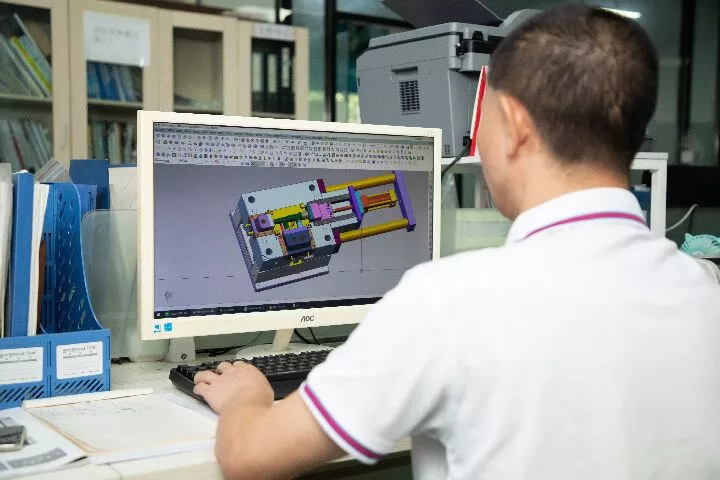

Mold Design and Making

Along with making top-notch injection molded medical devices, what sets a contract manufacturer apart from a typical parts maker is the ability to design and make molds for parts production. Creating custom molds for specific parts helps businesses expand their horizons, allowing them to offer more distinct plastic components to a wider audience.

Mold design and tooling are where Seasky Medical excels among our peers, with our experts providing a one-stop solution through our custom mold making service. From creating detailed molds to prototyping and mold tooling, we apply strict standards in every step to produce the best results. We also utilize premium materials and the latest CNC machinery in crafting molds that can handle long-term use.

Production and Quality Control

Contract manufacturers understand that your brand relies heavily on the quality of the medical devices you offer. Additionally, with the medical industry upholding some of the strictest standards, your injection molded medical devices should meet these qualifications, if not exceed them. As such, you need to partner with a contract manufacturer that places production and quality control at the forefront of their manufacturing process.

Seasky Medical implements a 4-stage quality control process that runs alongside our standard quality checks after every production step. From sourcing raw materials from well-vetted suppliers and maintaining professional clean rooms to securing the latest injection molding machines and advanced inspection equipment, we take all precautions in providing world-class products.

Assembly

While most contract manufacturers produce the medical devices through plastic injection molding, they can also work on product assembly for larger or more complex devices. Product assembly helps streamline your supply chain and sourcing needs while making sure the completed medical devices still adhere to required industry standards.

One factor any reliable contract manufacturer should have is a solid assembly service specifically catering to medical devices. This includes operating a cleanroom to avoid contamination during the assembly process and various assembly options for different situations. Seasky Medical offers all of these plus more, making it a reliable option for businesses worldwide.

Packaging and Labeling

Wrapping up the injection molded plastic medical devices with proper packaging and labels goes beyond protecting the parts during transit. Product packaging also stands as your business’s first opportunity to leave a lasting impression, as it shows your commitment to quality.

When searching for an ideal contract manufacturer to partner with, make sure that their packaging workshops maintain high levels of cleanliness. Seasky Medical, for instance, operates Class 7 and Class 8 clean rooms for safe and hygienic packaging. Custom labels are also added on the packaging, helping your customers better identify the products and cementing your brand with each purchase.

Regulatory and Certification Compliance

Manufacturing plastic medical components through injection molding not only requires refined technique and skill but also a good understanding of global regulations. The medical industry has strict rules for component production, and meeting these demands is crucial to the success of a medical parts business.

Seasky Medical maintains ISO 13485:2016-certified clean rooms that we utilize in manufacturing plastic injection molded parts for the medical industry. We also adhere to ISO 10993 biocompatibility and chromatography to determine suitable materials based on tolerance and precision needs. These steps guarantee that your components meet the standards set by local and international organizations, securing marketability and sales.

Market Support

Your partnership with a contract manufacturer shouldn’t end at order fulfillment – they should also be able to help your business bring the products to market. Whether it’s through product validation or importation assistance, a dependable contract manufacturer will make your sourcing experience as smooth and seamless as possible.

Customer support is also a crucial part of after-sales, where dedicated specialists can address inquiries and concerns regarding the product. This also involves handling product replacement when necessary, so you can focus on growing your brand while building a stronger relationship with customers.

Benefits of Working with a Medical Device Contract Manufacturer

As a medical device business, you might be asking why you should work with a dedicated medical device contract manufacturer. Although you do have the option of handling the entire process yourself and simply outsourcing the production to a third-party parts maker, you’re getting more with a contract manufacturer.

The contract manufacturer you choose to work with takes care of the entire plastic injection molding production on your behalf by leveraging their years of industry expertise and established network. They ensure that your medical devices not only meet industry requirements but also go from concept to store shelf faster and better. Moreover, with access to the right materials, equipment, and manufacturing expertise, you’re saving more time and money in the process.

But more importantly, medical device contract manufacturing services let you focus on what you do best – marketing your products and developing your brand. With their specialized capabilities by your side, there’s less to worry about and more to look forward to.

Seasky Medical – Your Trusted Medical Injection Molding Factory in China

When it comes to contract manufacturing for plastic injection molded medical devices, your search ends with Seasky Medical. We’re one of the leading injection molding brands in China with a strong drive for excellence, with a well-established factory located in Shenzhen. Our facility has multiple workshops fully equipped with the latest machinery and ISO-certified clean rooms.

Backing up our commitment is over 10 years of manufacturing expertise and 11 years of project management inherited from our parent company. Our team fully understands the rigorous product and manufacturing requirements of the medical field and implements the strictest quality standards in every step of the process. Plus, you’ll be working with a dedicated project manager who will oversee your project until completion.

Work with a Reliable Medical Device Contract Manufacturer

Medical device contract manufacturers provide medical device brands with flexibility and diversity to make their product sourcing smoother and convenient. Their experience, skill, and wealth of production capabilities in injection molding medical devices ensure your project is completed according to your preferences. Partnering with a reliable contract manufacturer will be key to the success of your project, taking your business to greater heights.

Looking for a medical device contract manufacturer for your next project? Contact Seasky Medical today and see how our expertise can match your production requirements.