Material traceability in medical molding is the ability to link each molded component back to a specific raw material lot under controlled manufacturing conditions.

It is a foundational control used to manage regulatory risk, investigate quality events, and limit the scope of corrective actions.

In medical injection molding, material traceability is not treated as a separate tracking tool.

It is embedded into procurement controls, molding process records, and change management workflows that govern daily production in regulated medical device contract manufacturing environments.

What Material Traceability Covers in Medical Injection Molding

Material traceability focuses on raw material identity and usage history rather than finished-device labeling alone.

Its purpose is to preserve a verifiable link between material behavior and part performance.

In a typical medical plastic injection molding operation, traceability connects:

- Resin supplier, grade, and certification status

- Material lot number and receiving date

- Drying, storage, and handling conditions

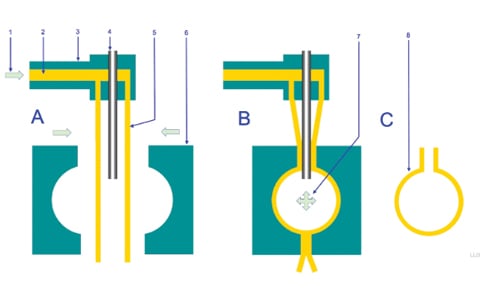

- Injection molding machine, mold, and cavity

- Approved process window and production run

These linkages allow manufacturers to reconstruct how a part was produced if deviations or complaints arise.

How Material Traceability Is Implemented on the Shop Floor

Material traceability is established through controlled handoffs between material management, molding operations, and quality records.

Each stage adds traceable identifiers rather than relying on a single document.

Raw Material Receiving and Segregation

Medical-grade plastics are received with supplier documentation and released through internal inspection.

Each lot is assigned a unique internal identifier before entering production.

Material selection decisions are typically managed through structured medical grade plastics selection processes to ensure consistency across product lifecycles.

Common controls include:

- Physical segregation of material lots

- Dedicated labeling for containers and drying hoppers

- FIFO usage to reduce aging-related variability

For applications involving elastomeric or soft-touch components, materials such as LSR injection moulding and TPE injection molding require additional handling discipline due to sensitivity to contamination and processing conditions.

Material Usage During Injection Molding

During production, the material lot is recorded against each molding run.

This links physical parts to specific processing conditions.

In cleanroom injection molding environments, material traceability also supports contamination control by ensuring material flow remains predictable and auditable.

Typical batch records associate:

- Material lot and colorant or masterbatch lot

- Injection molding machine and mold ID

- Cavity identification for multi-cavity tools

- Set parameters within a validated process window

- Operator, shift, and production date

When a single material lot is used across multiple machines or tools, traceability records preserve this relationship to support later investigation.

In-Process, Assembly, and Packaging Traceability

Traceability continues beyond molding.

Lot identification is carried through inspection, secondary operations, and packaging.

This includes controlled medical device assembly and validated medical device packaging activities, where lot continuity is maintained to support downstream audits.

Finished goods retain a production lot that references upstream material data.

This allows manufacturers to trace:

- Finished shipments back to resin batches

- Resin batches forward to affected products and customers

Traceability Within an ISO 13485 Manufacturing System

ISO 13485 does not mandate a specific traceability format.

It requires manufacturers to define and consistently apply controls appropriate to product risk.

In medical molding, this typically relies on:

- Controlled documentation and revision management

- Batch-level production and inspection records

- CAPA processes linked to material and process data

For ISO 13485 medical molding suppliers such as SeaSkyMedical, material traceability is treated as part of routine process discipline rather than an audit-only requirement.

Audit and Investigation Scenarios Where Traceability Is Tested

Material traceability is most often examined during non-routine events.

Audits and investigations tend to focus on whether records form a complete and consistent chain.

Common trigger scenarios include:

- Field complaints linked to mechanical or chemical performance

- Sterilization-related material degradation

- Supplier material changes or discontinuations

- Internal nonconformances during inspection

In these cases, auditors typically expect manufacturers to demonstrate which material lots were affected, how they were processed, and where finished parts were distributed.

Change Control and Material Traceability

Material traceability becomes critical when changes occur.

Resin substitutions, supplier changes, or grade updates introduce performance and regulatory risk.

These changes often intersect with tooling decisions, making coordination with medical mold making and early mold tool design controls essential.

Effective systems require that:

- Material changes trigger documented risk assessments

- Compatibility with sterilization and use conditions is reviewed

- Revalidation is performed when process impact is identified

Advantages of Robust Material Traceability

When properly implemented, material traceability supports both quality stability and regulatory readiness.

Typical advantages include:

- Faster root cause analysis during investigations

- Targeted recalls limited to affected lots

- Clear audit trails during inspections

- Improved supplier performance monitoring

Practical Limitations and Operational Trade-Offs

Material traceability does not eliminate quality risk.

It makes risk visible and manageable.

Common constraints include:

- Increased documentation and record maintenance

- Dependence on disciplined data entry

- Integration challenges between suppliers and contract manufacturers

High-volume medical consumables often require balancing traceability depth with production efficiency.

Applications Where Material Traceability Is Most Critical

Material traceability plays a significant role in:

- Medical consumables and disposable devices

- Fluid path and patient-contact components

- Micro injection molding applications with tight tolerances

- Medical insert molding where multiple materials interface

In these applications, material behavior directly influences safety and functional performance.

Traceability in One-Stop Medical Molding Services

When medical molding services extend from design through production, material traceability must remain continuous across phases.

This includes early product development, 3D prototype printing, pilot builds, and validated manufacturing.

In one-stop medical molding services, consistent material records support smoother transitions and reduce revalidation risk as volumes scale.

Closing Note

Medical molding companies handle material traceability through disciplined process integration rather than isolated tracking tools.

When embedded into daily manufacturing control, traceability enables predictable responses to quality events and regulatory scrutiny.

For projects involving OEM medical components manufacturing and controlled medical injection molding, Contact SeaSkyMedical for more information.