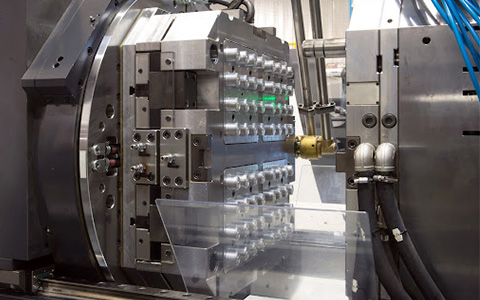

Durable and reliable medical-grade components that meet FDA standards ensure the safety of patients at all times, and one way of producing them is through injection molding. It is a go-to procedure for manufacturing state-of-the-art medical plastic products because it offers its users countless advantages.

Although there are many great features of the process, the best of them is its accuracy and consistency at pocket-friendly rates. Besides, it comes in handy when the production volume is very high and demands a masterpiece level of quality. With its smooth and seamless operation, medical plastic molding edges out similar production processes in the industry and offers various advantages.

Anyone wishing to get in touch with reputed and reliable medical plastic injection molding companies across China must check out this list. Here we have listed the best medical injection molding company offering high-quality products to clients. By connecting with them, one can be sure of purchasing durable, reliable, lightweight, and affordable medical components.

List of 6 Medical Plastic Injection Molding Companies:

1. Seaskymedical

Seaskymedical is one of the top companies of medical plastic injection molding in China, manufacturing high-quality and durable medical plastic injection devices and components for over 10 years. By employing advanced technology to the production challenges of medical products and reducing the risk by providing professional and sincere service, it strives to enhance each customer’s experience.

Specializing in manufacturing injection molding for the medical sector and offering them low-risk solutions, Seaskymedical is the go-to company worldwide. It also provides all-inclusive and professional support at all project stages, including product development, mold design and manufacturing, material selection, and cleanroom injection molding production. Its Class 7 & 8 Clean room and various molding technology enable it to manufacture all sterile medical molded products.

2. Rilong

Rilong is a medical plastic injection molding company established in 1990 in Shenzhen. It is popular as the original supplier of high precision plastic injection equipment, chiefly exported to the US and Japan. But in 2006, it underwent a significant transformation by setting up a rubber house in Dongguan.

With a team of over 300 skilled and experienced members, it provides its customers with 100% in-house manufacturing solutions for developing its products. Today, its production line mainly focuses on mold design and manufacturing plastic and rubber molds, double injection, LSR over mold, and hard & soft plastic over-mold parts.

3. Silver Basis

Another reputed and reliable medical plastic injection molding company on our list is Silver Basis. Since its inception in 1993, Silver Basis has been a market leader in this industry. For a long time, it has been producing molds and collaborating with renowned car companies, such as Peugeot, and Chinese electronics behemoths, such as ZTE, to offer high-quality products to their clients.

With over 8 facilities across China and 300 craftsmen having more than a decade of experience, it strives to offer its clients the finest products.

4. Bluestar Technology

Established in 2003, BSM Group is another renowned Chinese medical plastic components manufacturer on our list. It has nearly 100 members specializing in mold designing and vehicle parts manufacturing for well-known companies, such as Philips, Whirlpool, CAPSA, GAC Mitsubishi, Renault, Nissan, Honda, Toyota, and others.

Today, it employs over 800 people at facilities worldwide, including in China, America, and Europe. The central focus of Bluestar Technology is manufacturing automotive parts, lighting parts, and EV BMS. It is also popular for creating injection molded parts for white goods, home electronics, and other applications.

5. JMT Mould

Being a subsidiary of Taizhou Huangyan, JMT Automotive Mould is a leading manufacturer of high precision machines across China, meeting European and American standards. With over 20 years of rich experience in automotive mold making, today has become a household name worldwide.

JMT Mould is among the best medical plastic injection molding companies in China and worldwide. It also provides customers with one-stop services, including fabrication, mechanical design, plastic products, prototyping, and secondary process service. As a popular mold maker and exporter, it also has strong quality and order control management.

6. Richfields

Founded in 2001 by several private investment groups from Hong Kong and staff with decades of experience, Richfields Corporation is a renowned medical plastic injection molding supplier across the globe. It uses mold flow analysis programs to ensure the potential processing programs are highlighted at an early stage, right before manufacturing components.

The firm offers a range of products to its clients, such as precision plastics, rubber molds, family mold, over mold, medical plastic injection, hot and cold runner mold, and air assist. Its customer service strives to reduce the response time while providing quality products at a competitive price.

The Importance of Medical Plastic Injection Molding:

Here are the top six reasons to consider the plastic injection molding procedure for making medical devices:

Offers Control and Reliability

Medical plastic injection molding is suitable for creating the highest quality plastic medical products as it is very stable and reliable. It uses advanced modeling software that takes most of the guesswork out of the tool design and allows the molding manufacturers to quickly tune the process parameters for optimal performance.

The medical injection molding method also helps reduce the production lead time to a minimum, reducing the cost of medical equipment.

Manufactures in High Volume

Under this process, making a complex medical product’s shape means making an equally complex mold tool. So, before making a product, designing and developing investment is made. Once the equipment is approved, the right medical device injection molding companies can make thousands of duplicates quickly and economically. Large production volumes recoup the tooling cost over time because of low price-per-part.

An Ideal Solution for Enclosure

When manufacturing medical device cases and enclosures, plastic injection molding is ideal because, unlike other production methods, it is quick, consumes less raw materials, and its cost-per-part is low. It is the reason a different production procedure makes more sense only for low-volume or custom jobs when one doesn’t want to invest in a tool.

The plastic medical molded products made through this method have a quicker production time, a low cost-per-part, and medical-grade plastics, making them ideal for cases and enclosures.

Versatility for Medical Equipment

The plastic resins used for manufacturing medical equipment have mechanical and chemical properties, making it simpler for a manufacturer to pick the most appropriate ones for end users and the environment. One can choose among resins that are heat stable, biocompatible, chemically resistant, biodegradable, lightweight, and strong.

With a wide variety of low-cost and quality resins for producing plastic injection molding medical parts, it is essential to find the best fit for their devices.

Factors You Need to Consider When Choosing A Medical Plastic Injection Molding Company:

Here are the top 6 factors one needs to consider while choosing a medical plastic injection factory:

Production Volume & Capacity

If you are going to carry out medical plastic injection, the first thing you need to consider is injection molding medical plastics. The quality of raw plastic material will influence the durability of medical devices and medical plastic consumables.

Provides a Range of Services

A company that offers one-stop manufacturing solutions from a part’s design and concept stage can help create optimal designs within budget for your medical project. One must cooperate with medical plastic injection molding suppliers that offer a complete range of services – part design, prototyping, and mold flow analysis.

An Experienced Design Team

Since design is one of the essential aspects of medical plastics, one should go for medical plastic molding manufacturers with a great design team and one that gets involved at the early production stage to achieve the objectives. Considering this factor goes a long way in ensuring the desired results, minimizing part usage, increasing the return on investment, and deciding the overall budget.

Application of All the Products

A medical device injection molding firm that guides its users in selecting the right plastic resins for different applications, based on the end use of a product and their budget, while assisting them throughout the various stages of manufacturing is the best.

Specifications & Technology

One must partner with a company that provides medical plastic parts according to the specifications. It must guide them throughout the manufacturing procedure and make suitable suggestions based on the required specifications. An ideal plastic injection molding firm should have the experience, knowledge, and technology required by the customer.

In-house Quality Assurance

A company with an established in-house quality assurance team to monitor the process is crucial. Since the plastic market is highly competitive, one should buy from a firm that provides assured plastic medical parts and efficient services.

So, conduct a quick background check on the reputation and performance of the molding firm. It should meet the desired quality standards and have ISO certification to be eligible.

Find A Reliable Medical Plastic Injection Molding Factory – Seaskymedical

Anyone looking to mold medical plastic components from a reputed manufacturer may turn to Seaskymedical without a second thought. It is among the rare companies considering various time-taking steps like design revisions, part complexity, and discussions with designers and engineers to deliver their medical products on time.

Seaskymedical applies advanced injection molding technology to all its production challenges to provide the medical sector with the safest and most reliable equipment. The firm has been offering low-risk and affordable solutions to the healthcare sector for over ten years. Besides, it provides its clients with all-inclusive and professional support at all the project stages.

Anyone wanting to partner with a firm having more than ten years of experience in project and supply chain management to meet the diverse challenges of the medical and healthcare sector should consider tying up with Seaskymedical. To buy high-quality medical products and equipment to ensure to health and safety of the patients, please contact us.