Crafting medical injection molded components doesn’t end at molding and extrusion – they need to be refined to enhance their qualities and improve performance. They also require additional treatments to make them compatible with safety regulations prescribed by local and international bodies. This is what we call surface finishing, which is part of the secondary operation process.

This article will examine some surface finishing techniques we use in creating plastic injection molded parts for medical equipment. We will also look at where these techniques work best, so you can choose the right treatment for your next project.

Key Surface Finishing Techniques for Medical Injection Molded Devices

Polishing

For plastic injection molded medical equipment, polishing is important not only for refining the parts but also for improving their quality and performance. The process is commonly used in finishing parts for surgical equipment, catheters, pharmaceutical equipment, and other medical devices.

Several options are available for polishing the parts, each offering distinct advantages and applying to specific finishing requirements. These include:

- Mechanical polishing – uses abrasive tools like grinders and buffing wheels to remove excess material and develop a smooth, clear surface.

- Chemical polishing – the parts are dipped in meticulously calibrated chemical solutions to dissolve material, resulting in a well-polished and even surface.

- Electropolishing – after submerging the parts in an electrolyte-rich solution, electrical current is introduced to gradually dissolve the surface layer, revealing a smoother surface.

Abrasive Blasting

Abrasive blasting is a reliable surface finishing process that also doubles as an intermediary secondary operation. This is typically used on smaller injection molded medical parts, including screws, orthopedic equipment, and the like.

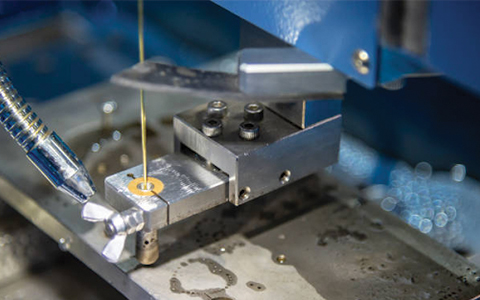

The process is done through a specialized technique called microblasting, where tiny, high-grit particles are blasted to the part surface via compressed air. This effectively removes any contaminants and smoothens the surface from burrs or excess materials, while dramatically improving the surface texture. It can also prepare the part surface for other surface coating processes, ensuring proper coat adhesion and stability for long-term performance.

Vibratory Finishing (Tumbling):

Vibratory finishing is typically used for processing high volumes of small component, like surgical instrument handles and connectors. This finishing technique removes sharp edges or flashes on completed parts that could compromise the safety or comfort of the end-users.

In this process, the injection molded parts are placed in a vibratory tub containing various abrasive media, also called a tumbler. The machine then vibrates for a certain time period, causing the media to brush along the parts to deburr, smoothen edges, and clean uneven surfaces. The abrasive media is selected based on the certain factors, including the part size and desired finish.

Etching (Chemical Texturing):

Also referred to as chemical texturing, etching utilizes a combination of a protective mask and chemical solutions to smoothen injection molded parts. It is also a reliable method of adding definitive patterns on the part’s surface, improving its performance and aesthetics.

Patterns are applied to the surface of the injection molded parts, which are then dipped into a controlled chemical bath or the etchant. Once the etchant has eaten through the unprotected sections, the parts are taken out of the bath, along with the mask. They are then rinsed and wiped clean to remove excess chemicals, revealing the desired pattern on the surface.

Etching is used to produce fine details on the injection molded parts that control fluid flow. The patterns also enhance cell adhesion for diagnostic components.

Physical Vapor Deposition (PVD):

A common secondary processing technique used in injection molding is, vacuum deposition process (PVD) is used to apply a thin, hard coat of metal or ceramic on the part’s surface. In this process, the injection molded parts are placed in a vacuum chamber after a thorough cleaning, where the vaporized material is then released into the chamber. The coating material then adheres to the part surface until a thin film forms, covering the part completely.

Injection molded parts finished through PVD have extreme wear resistance, hardness, and chemical inertness, much-needed qualities in various medical equipment. The process is applied to surgical cutting tools, orthopedic instruments, and specific components that require a medical-grade non-stick surface.

Antimicrobial Coatings:

A surface finishing treatment integral to many injection molded medical equipment, antimicrobial coatings hinder the growth of harmful microorganisms by coating the surface with antimicrobial agents. These agents include silver ions, copper, or other materials, creating a layer that self-cleans and extends the service life of these products.

Applying the antimicrobial coating can be done through several means, like spray coating, dip coating, and electroplating. The process is used on high-touch surfaces and equipment constantly exposed to harmful bacteria, including device housings, bed rails, and handheld instruments.

Plasma Treatment:

For injection molded parts that require surface modification without changing their physical properties, plasma surface treatment is a viable option for the task. This can be done either through a vacuum chamber similar to PVD or at atmospheric pressure.

The process involves ionizing the gas treatment material, turning it into plasma, then exposing the part to the highly charged plasma. This causes the plasma to interact with the part’s surface, creating a protective layer that not only removes contaminants but can also etch the surface. The protective coating makes the part surface more receptive to bonding, painting, and printing, which is crucial for multi-material medical devices.

Nanostructure Modification:

More of an intermediary process than a final surface finishing technique, nanostructure modification controls the part surface on a nano level in preparation for another process. The process is typically used in creating drug delivery devices and high-precision components in the medical field.

Whether done through the top-down approach that breaks the part’s structure or the bottom-up approach that builds atoms on the surface, it helps minimize part deformation during the assembly process. Some methods used in nanostructure modification include physical methods, chemical treatments, and thermal exposure.

Material Considerations for Surface Finishes

Despite the versatility of surface finishing, not all methods apply to every situation. As such, it’s important to go with the right process to achieve the optimal results.

Here are some factors to consider before choosing a surface finishing technique to implement on your plastic injection molded medical components:

Ductility and Hardness

First, factor in how ductile the plastic is, or its ability to deform without breaking or losing integrity. More ductile materials can handle burnishing better, while elastic materials may require chemical polishing for proper finishing. As for hardness, remember that harder plastics may need specialized equipment compared to softer ones, thus adding to manufacturing costs.

Compatibility

Next, there’s how the material adapts to the surface finishing treatment to be used. For instance, some materials may dissolve during etching, making them incompatible with the process. Other plastics may cause the deposited layer to chip off easily when finished via PVD, so the process won’t be a good option.

Plastic Quality

Another point of consideration is the quality of the plastic you’re using for the injection molding project. Some plastics may adapt well to a direct surface finishing technique, while others may require an intermediary process like nanostructure modification to improve their adhesion.

Future Trends in Surface Finishing Technology

The plastic injection molding industry continues to develop, adapting emerging technologies to take parts production to the next level. Some innovations that are showing gradual use in the production of plastic injection molded medical parts include the following:

Virtual Simulations

The emergence of digital technology is being embraced, making the surface finishing process faster and more technical. Through virtual simulations, engineers can foresee how the surface treatment will affect the final injection molded part and make changes even before the prototype.

Advanced Materials

New coating materials are being developed to improve the longevity and quality of the final injection molded parts, like composite resins. To accommodate the new materials, new methods are also in the works for optimized results.

Sustainable Surface Finishing

As the world slowly transitions into sustainability and eco friendliness, surface finishing materials and processes are being adapted by manufacturers. This includes opting for water-based materials and recycling abrasive media, among others.

Elevate Your Plastic Injection Molded Medical Parts with Surface Finishing

Surface finishing is an important part of the injection molding production workflow, as it cleans the parts of any excess material after molding and extrusion. Additionally, it enhances the durability, performance, and longevity of the completed part, further adding value to the components.

There are various surface finishing options available for brands to choose from, each offering certain advantages that fit specific applications. Knowing which technology to implement on your project requires some consideration, including the material’s ductility and quality. Contact Seaskymedical to start your next injection molded medical component project today. We offer the latest surface finishing technology in the industry and have experts who can guide you in selecting the best one for your needs.