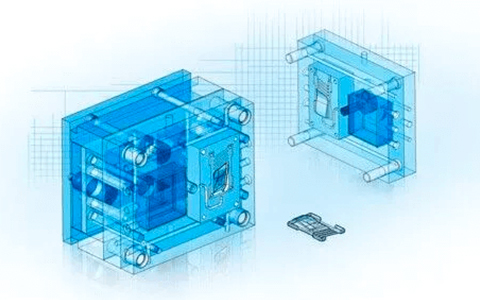

Injection molding is awfully the ultimate method for fabricating multiple features and pieces. It gets broadly operated for assembling similar components with tight patience. Contract medical device fabricating can be a low-cost and exceptionally reproducible mechanism that delivers superior elements for enormous series fabrication.

Understanding the outlays of creating an injection-designed part is essential prior to consider it for the assembling procedure. The injection molding cost can vary between $5,000 to more than $150,000, determined by the size demanded, part intricacy, and additional aspects. Insert molding may be costly while setting up, yet it is inexpensive throughout eventually, so it performs soundest for immense fabrication volumes (Check: Insert Molding Process)..

There are many aspects influencing the entire cost that would get paid for injection-developed medical equipment, covering the resin’s expense solely, mold cavitation, cycle time, tooling, and additional factors.

Why Is Injection Mold Cost Expensive?

Price is constantly a vital concern when selecting the finest medical device injection molding method for making plastic parts. Because plastic parts made by insert molding are typically shorter and more complex against those made by rotational casting, there is inherently a lofty acquisition of labor and time applied to completing them, which may eventually expand the plastic molding price.

Since there is usually a compact size limitation on the type of pieces that might get assembled by injection casting, it suggests that various distinct instruments must get fabricated to create all the components utilized to complete the sizeable finished product.

Factors Related To Injection Mold Cost

Being mindful of every aspect that might influence the cost of the final outcome is extremely necessary, specifically if someone is unfamiliar with the existence ofcustomized injection molding. Not just will this support the core, but it may even help to perform beside the contract medical plastics manufacturer and create a more low-cost product.

Injection Mold Tooling Cost

Tooling prices rely on how intricate or vast the components might be. If the part is complicated (for instance, if it has a complex shape or thick borders), the manufacturer might require operating a more costly device to conclude the order.

The injection molding tooling cost rises aggressively if the concern is about the enormous customized piece. The contractors say it is desirable to utilize compact (desktop) insert molding devices also 3D printers for satisfying small quantity orders.

Enormous commercial plastic molding company devices may evaluate above $200,000 and include other costs linked to professional labor activity, supervision, observing, also industry limitations. These types of instruments get dedicated to extensive orderings.

Mold Classifications

The insert SPI mold classifications determined by the Plastics Industry Association set measures on the material device structure and longevity. By choosing a suitable mold category according to need, people may preserve compelling expenditures by not overcomplicating the product.

For deciding which mold type is best to proceed with, starting with the tool resources and longevity may be a good beginning point. If the product has concise longevity with a product-standard material or an innovative standard not at all corrosive, one may begin at the prototype or Class 105 mold category.

- Mold Category 101- The mold bottom must be the lowest stiffness of BHN 280. Casting textures (cores or cavities) should get solidified to at least Rc 48. Additional elements, like heel blocks, slides, wedge blocks, gibs, etc., must be of toughened instrument metals. Thermostat requirements are to be in cores, slides, and cavities anywhere feasible.

- Mold Category 102- This mold is similar to 101 class with the subsequent objects not needed: accustomed slide wear plates, conducted ejection, wear plated cavities, and plated aqueducts. This instrument is a means to a higher-productive device suitable for corrosive materials and close-resilience outcomes.

- Mold Category 103- The mold bottom must be the lowest stiffness of BHN 165. Cavities and cores should be BHN 280 or above.

- Mold Category 104- The mold bottom may be aluminum and soft-cast metal. Cavities and cores should be soft-cast steel, aluminum, or somewhat united steel.

- Mold Category 105- This device is just for prototype objectives. The mold bottom can get created from cast steel, epoxy, or any additional material delivering adequate resilience to construct the lowest prototype parts.

Mold Complexity and Aesthetics

Extremely complicated structures with additional cavities and excessive mold refinement can cost extra. These configurations demand analysis, expansion, and high-tech skills. Accordingly, one may employ a proficient or outsource the configuration procedure. Both prospects attract expenditures.

Gate

The gate is the starting portion of the cavity that lets the molten material infiltrate. The configuration and place of a gate hold an enormous impression on course times, tooling expenses, and correctives of the concluded piece.

Multiple gate configurations are accessible that rely on the preferred form, elegance, and size of the product. Listed down are some of the most familiar:

- Sprue or Direct Type: By this configuration, the sprue straightly feds the piece. These are generally uncomplicated to conceive and fabricate because there is no gate or runner. This design has the advantage that no resource gets destroyed by casting a gate or runner, and an enormous piece can get filled with this configuration.

- Edge Type: This gate is equilateral, where it handles the position and decreases in height and width of the runner. By this gate category, the plastic goes where the 2 mold parting lines connect, stuffing the cavity from the edge of the piece and demanding that the entrance disassembles after shaping. The depletion in dimensions through the runner permits to disrupt nearly to the component, separating a compact equilateral fragment or noticeable gate leftovers on the element. This gate structure is usually reasonable.

- Hot Tip Type: By this gate category, the plastic is reserved liquefied to the part chamber utilizing boilers, eradicating the runner, gate, and sprue and decreasing the share of primal resources employed. The hot tip entrance outcomes in a small remnant and lessens the processing time. This type of entrance is generally costly and habitually economical for higher productivity runs.

- Tunnel Type: This entrance falls under the two halves, so the cavity is sealed from beneath, permitting better resiliency in the entrance area and better command at the scar area. This entrance type has the benefit that the runner and part get impulsively disconnected in the ejection phase.

Moreover, most shapes get built of two plates, but if the 2-plate frame fails to provide an appropriate gate area, the 3-plate mold can get employed. 3-plate molds even let a better detailed, diagnose-style gateway design on the surface level of the component.

As anticipated, 3-plate molds are actually expensive, specifying the surpassing instrument complexity and carving needed. These configurations get frequently utilized when a piece is enormous for a 2-plate frame or better insert pinpoints are required.

Cost Of Injection Molding Materials

Determined by the requirements of the final outcomes, a wide range of synthetic resins can be operated for insert molding (Learn: 101 Injection Molding Runner Design Guideline).

. The expense involved when plastic injection mold materials are purchased contrasts determined by the resources specified. In injection molding price, the thermoforming resin shells vary between $1 to $5 a kilogram.

Resources cost gets regulated by the configuration of a project, the resource used, and the material required to conclude the insert molding procedure.

Injection Mold Machine Cost

In insert shaping, special-designed supplies differing from small private molding devices that industries might use internally to big commercial injection molding tools mainly controlled by suppliers, fabricators, and prime medical components manufacturer get used.

With compact desktop injection shaping tools and additive manufacturing molds, forming subtle portions of elements with insert shaping is the utmost low-cost. Minuscule motorized injection molding mechanisms are possible alternatives for the middle-series fabrication of little parts.

Enormous commercial injection shaping devices may vary between $60,000 to higher than $200,000. These devices even hold more stringent structure provisions and the demand for the technical team for functions, maintenance, and observation. Subsequently, even if insert shaping is a core proficiency, most companies prefer outsourcing assembly-line production to service suppliers and agreement producers, with tool expenditures incorporated in the price points.

Cost Of Injection Molding Labor

Numerous stages concerned with insert shaping are computerized and operated by application software. Nevertheless, there will be a few specific labor expenses, as detailed down:

Assembling Prices: There are precise design conditions for each step in injection molding. For example, while creating the shapes, a few configurations of tools are demanded. And putting up the mold and designing the tools throughout insert molding all require a machinist’s time.

Machinist Prices: Not considering the self-operating equipment employed, a machinist should manage the procedure. The price of the machinist is something to be considered in the labor expenses.

Restoration Prices: Plastic resin molding is an automated process demanding numerous types of tools. Accordingly, there are determined to be upkeep and restoration procedures that come out as outlays.

Production Volume

The production prices for each piece decrease if the manufacturing happens in enormous amounts. The exact conception maintains for insert molding likewise. While satisfying an enormous volume of production, a proportionately immense number of shapes will get demand. Nevertheless, the price for the frames does not grow straightaway.

For instance, if injection molding mold cost is $1 a piece for 100 pieces, the expense for five thousand pieces will be approximately $0.5, and for 100,000 frames, it may get to $0.25 apiece.

Variables That Impact The Injection Mold Cost

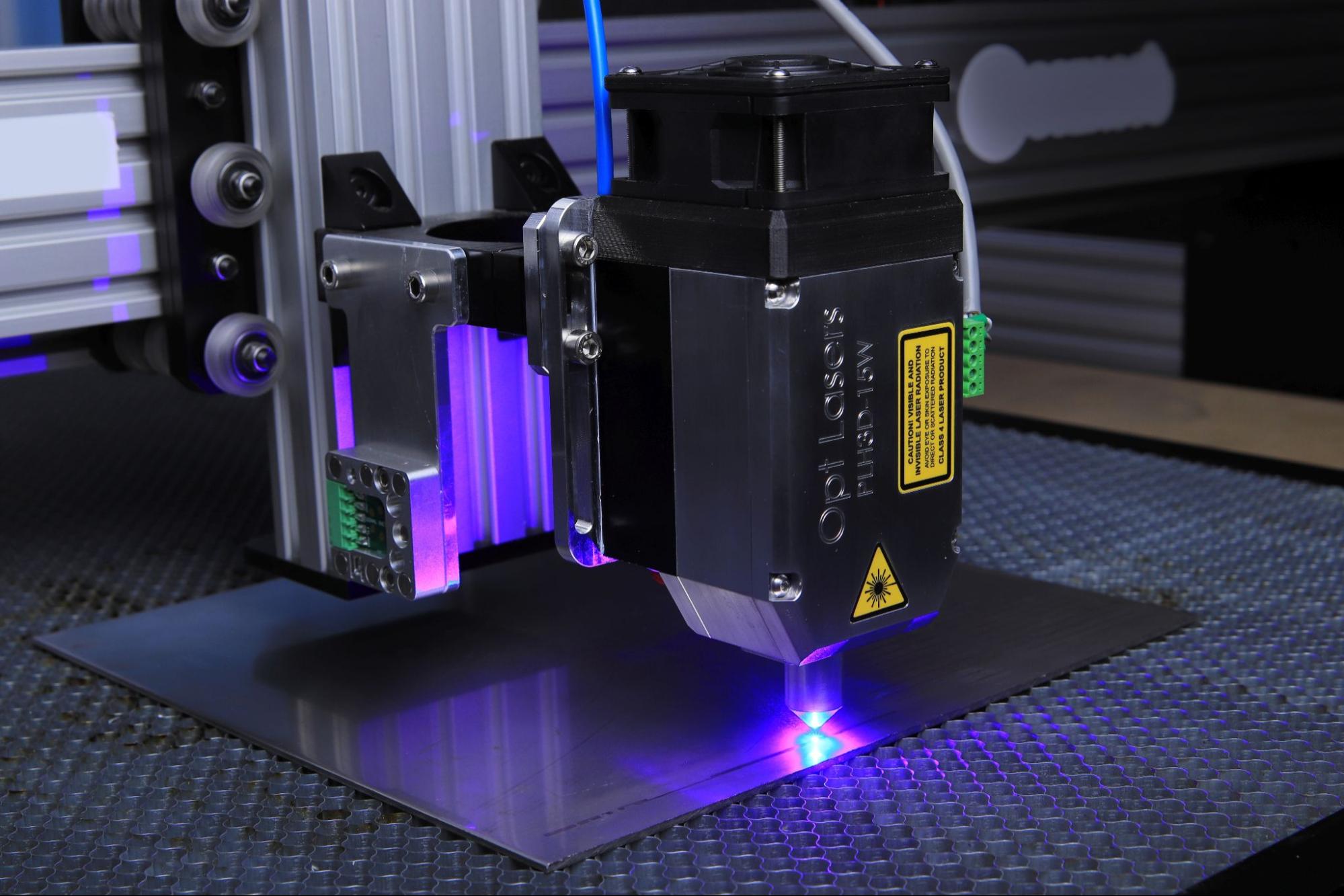

Tooling expenses for custom plastic molding cost are exceptionally lofty. Diverse aspects impact these expenses, together with particulars such as textures, living hooks, and inserts and their various stages of sophistication. The forms get generally shaped utilizing a Computer Numerical Control device operation and include metal and aluminum. Electrical discharge machining and 3D printer procedures even get employed.

Other components that influence the procedure and may modify the expense contain the subsequent:

Injection Molding Cycle Time

Injection molding in clean room process time can take up to almost 60 percent of the closing part price. The piece value declines somewhat to process time and partly to deformation. Typically, processors might have specified hourly tariffs they impose for the devices.

The shaping process might get split into two series:

- Cooling duration: It illustrates about 8 percent of the whole process period. It laboriously impacts the standard of the afterpiece since it is the period it requires the resource to chill and diminish.

- Injection duration: It illustrates the time it holds for the material to get infiltrated into the frame. It is generally for a short while and relies on the device’s capability and hit dimensions.

Part Size

The better considerable the preferred part is, the enormous form it needs for shaping. Moreover, large frames demand additional resources to finish the deal. All these aspects merged advances to premium costs, specifically if contrasted with utilizing components with shorter dimensions.

Part Design

Parts created with extra complicated dimensions require casts with additional fragments to conduct the concluded product. Usually, mold designs contain a side A and B. Side A is concerned with the decorative side, as it is considerably softer as utilizers might consider it more. Side B contains concealed elements that facilitate the accurate operation of the component. These elements might have ribs and additional breaks.

If casts have complex structures bilaterally, they are generally loftier in expense to complete compared to uncomplicated designs. These models usually demand undercuts and diverse bottom lines, which enormously supplement the expenditure.

Plastic Weight

Plastic weight price encloses the plastic composed into components and the accustomed plastic residues in the frames. The expense of the moldable weight has also got to be covered not just in the elements yet in the gate, sprue, and runner, likewise (the sprue and runner are canals where smelted plastic passes through to incorporate into the frame, while the gate controls moldable from pouring out while it goes in).

For instance, if it turns out to be 4 lbs of components and 1lb of residue plastic that solidifies in the runner and sprue, it will require payment for 5 lbs. Fixed scrap amounts may likewise move into the concluding expense of insert shaping. Those are for cleansing the moldable insert molding devices of preceding plastics out of the screws and barrel, likewise refilling them with new plastics.

Production Volume

The overall portion of elements that must get fabricated utilizing the plastic injection molding procedure shows the construction approach and kind of resources utilized while making the model. Minuscule components use additive manufacturing that demands aluminum models, while wide-ranging projects require metal or multiple models to conduct the elements without subsequent wear impacting the concluded outcome.

It may affect the cost of the model; nevertheless, the premium cost for wide-ranging models gets outspread between a loftier amount of elements, which advances to an inexpensive cost per respective model.

Part Volume And Cavities

The element capacity is also called the cavity or cleared piece of the model. General cavity capacity or added cavities indicates a lengthier press duration is needed. Other press duration declines manufacturing time which increases the prevalent expense.

Secondary Service

If the processor demands added material selection and assistance like rubbing or consequent finalizing for the outcome, this symbolizes an additional outlay. Although it has nothing to do with the custom injection molding cost, the supplier may review it as an extra charge. Consequent assistance can vary in price, which might approach like:

- Added creating procedures, together with inserts, drilling, and machining

- Assemblage assistance, like sonic welding and bonding

- Embellishing or drawing, together with screen printing symbols or additional designs

Some elements might not require consequent assistance, although others need it. The low-priced components drop out of the device into a crate, yet superiors might form bound to the entrance. Those need pre-processing execution to clear the gate, but they get accustomed as gating causes the gross procedure more effective and less cheap.

How To Reduce The Injection Molding Cost?

The feature of a plastic mold cost is mainly determined by the intricacy and the time it consumes to complete it. As maintaining a low-cost approach for time-saving insert casting, it is equally crucial to recognize locations where attempting to hold finances can force massive problems eventually as it is to discover places to reduce the expense.

It gets advised to stick to design-for-manufacturing regulations to diminish part expenses with insert casting. The outlay of making a clean room injection molding might get lower by involving the subsequent procedure suggestions:

- Be straightforward with the tooling forecast. While trading with a producer, it is sounder to discuss what things can get managed from scratch. It is essential to recognize that plastic injection mold cost is higher, so it is not probable to keep the budget cost-effective on that portion of the procedure. Prices might, regardless, rely on the approach and whether attempting to create thousands or millions of parts.

- Recycle moldable trash. Using moldable that solidified in the runner & sprue and which got ceased in finishing may help decrease resource expenses. Nevertheless, a tiny portion of mechanical possessions gets reduced whenever the moldable and the extras get reused. So they can not get reprocessed repeatedly. For instance, glass stuffing fibers evolve briefer if they get used for reprocessed moldable, which increases a reduction in possessions like malleable and influence potencies. According to science direct, both resources can get lowered by up to 40 percent after numerous reprocessing efforts.

- Seeking a respected organization is essential. Prestigious providers hold rebuild potentials on-location that are helpful as tooling begins to break down. A reputed supplier will ensure the tooling survives up to 100,000, or even until countless cycles relying on the use.

- Acknowledge substitute elements beforehand. It might be an added expense, but it will finish as paying less at last. Review it as a kind of precaution while assembling for the poorest.

- Enhance design effectiveness. In the conception phase, it is essential to concentrate on the necessary segments that guarantee the best execution of the project. It is okay to encounter components that can be categorized as good to own but might not put up to the price tag of the part.

- Contemplate medical insert molding. It performs by inserting a product inside the moldable and wrapping it in synthetic plastic. It delivers the possibility of adopting plastic resin for two outcomes by operating inserts. Those inserts might then get released and positioned in distinct locations relying on the shared process. It is a universal strategy that will support lowering expenses.

- Think about how appropriate the component aspect is. Polished completion looks attractive, but is it necessary for the device? If it does not summarize expanded sales, consider terminating it.

Injection Mold In SesakyMedical

The plastic injection molding price may contrast relying on resources, mold cavitation, tools, packing, essential credentials, and added services engaged. While the task might hold stringent provisions for the performance of the preferred element, there are numerous methods for cutting expenses without surrendering standards.

Nevertheless, to be capable of doing this, understanding what precisely these sections are and how essential they are considering the task is necessary.

At SesakyMedical, the finest medical plastic injection molding company, we deliver problem-solving injection molding services from strategy to tooling to resource preference and fabricating.

Being enlightened about the influence of specific product qualities and determinations is necessary. It will support deciding what configuration satisfies the product requirements. But without wasting on excessive parts.

Conclusion

Insert casting is the utmost broadly involved fabricating procedure these days. People get to see and feel numerous elements constructed through this method, like plastic grips and bottle lids in their everyday life.

Comprehending the aspects contributing to expense might assist in enough ways. For instance, it allows conveying better with the mold fabricator. Just put the designs and necessary details into the contact us portal to begin, and our professionals will respond as soon as possible to go ahead with the features.