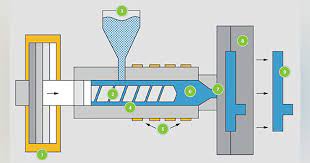

How do We Manufacture Injection Mold Tooling

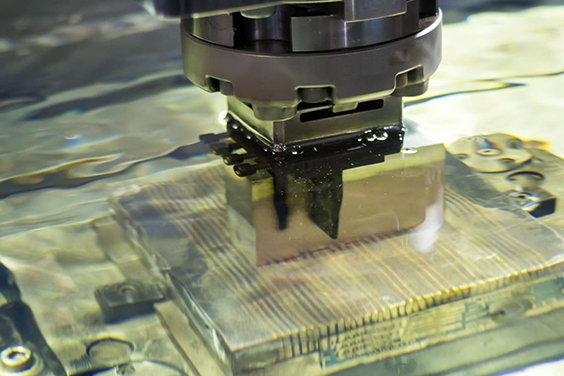

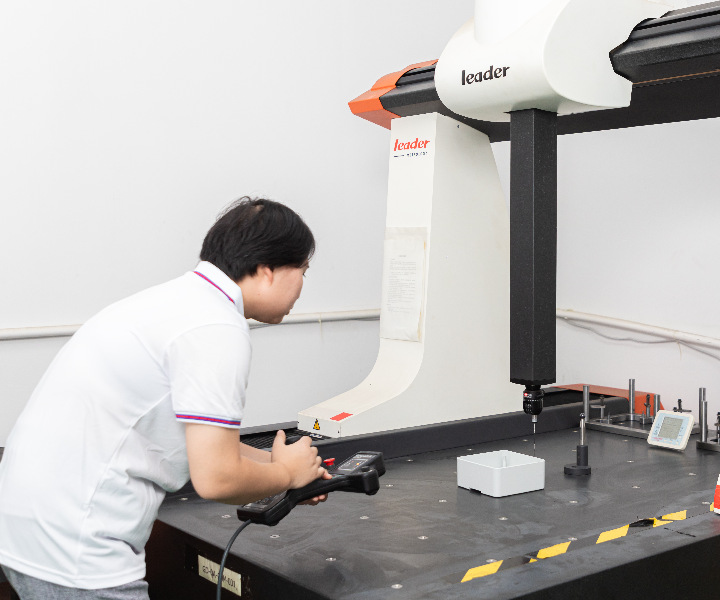

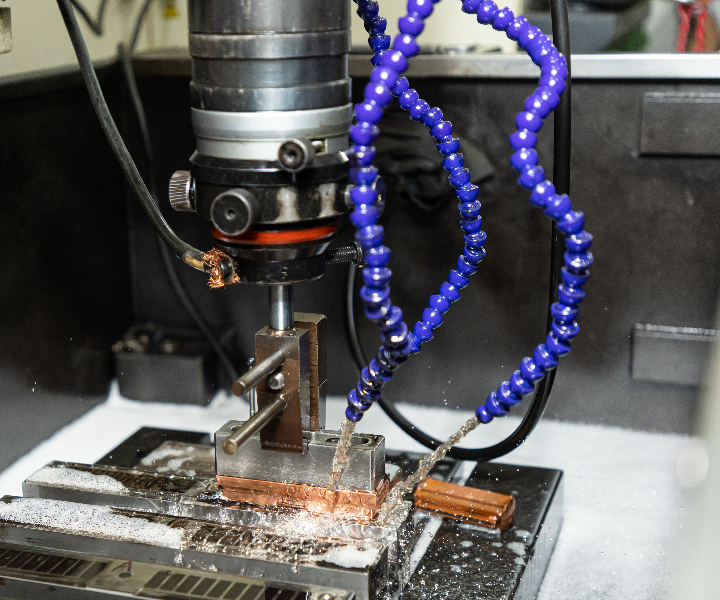

During the plastic injection molding tooling manufacturing process , there are several factors to take care of.

As a professional mold manufacturing company, Seaskymedical makes a flow analysis of the design to improve the functionality and suitability of the mold tooling.